Crepe

Aquarium Advice Addict

What kind of filter are you running on it? Just wondering. I may have missed it earlier in the thread.

I'm moving to a small apartment or efficiency so I won't have the room for it.I'm sure there are lots of people who would like to get a 250g at a discount... why can't you move it with you?

It is easiest to just show you what I am doing when it gets here...(it's all LED's but not 300 of them) that's what the pics are for300+ LEDs? Or is some of that in MH I hope?

100ish 3 Ups?

lol i'm impatient and this intrigues me.

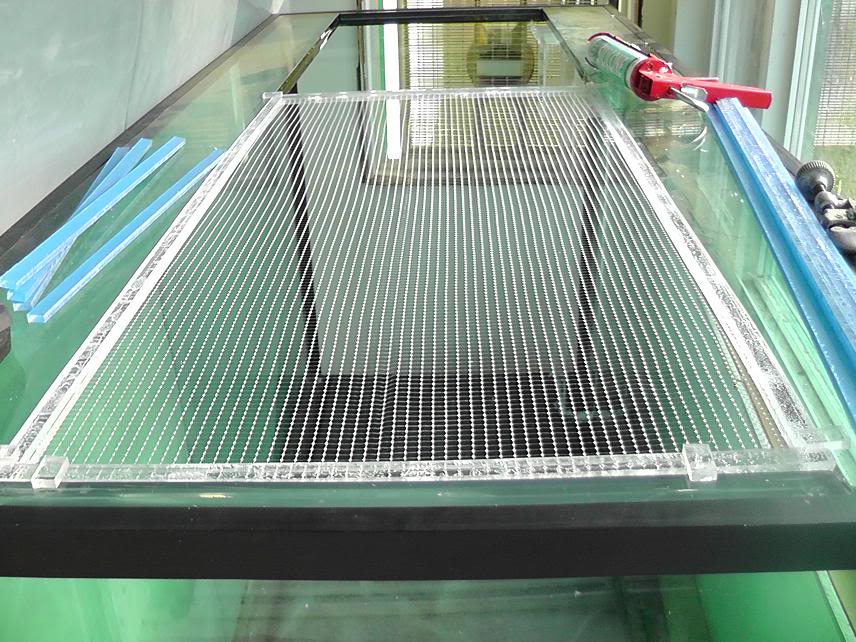

Fine... I'm having 45-55 LED dies each die has 20 1W diodes on it. The dies need good heat dispensation because all of the diodes are so close together. Hence the big @$$ heat-sink

Not sure who makes them and no there are no optics yet... I will see how the light is and if I need it I will add it after.Who makes these? Are you planning on using optics at all?

arghh wake me up when we're past the LED's...

Hopefully I can look back on this in years to come and understand what's going on

arghh wake me up when we're past the LED's...

Hopefully I can look back on this in years to come and understand what's going on