I'm leaning towards going with a sump for my 29g. The only tank I could fit below it in the stand would be a 5.5g, so that's the only size I could use for a sump.

I do have a few questions since I've never done anything like this.. First, I need an overflow. I cannot drill my tank anymore as it is already filled. My LFS sells overflow boxes for $30 and they seem to work fine as they have some on their tanks. I know the overflow will siphon-feed water from the main tank down into the sump.

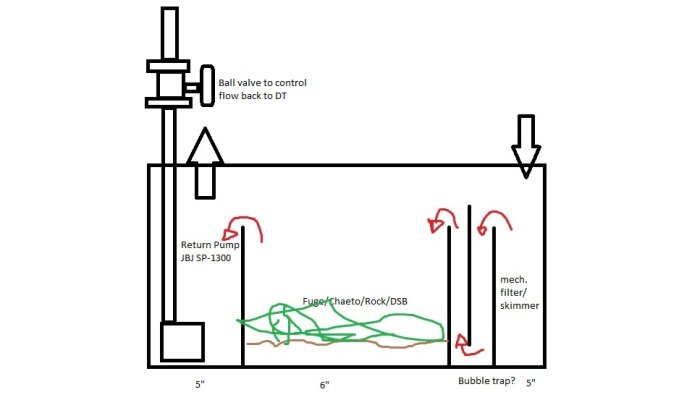

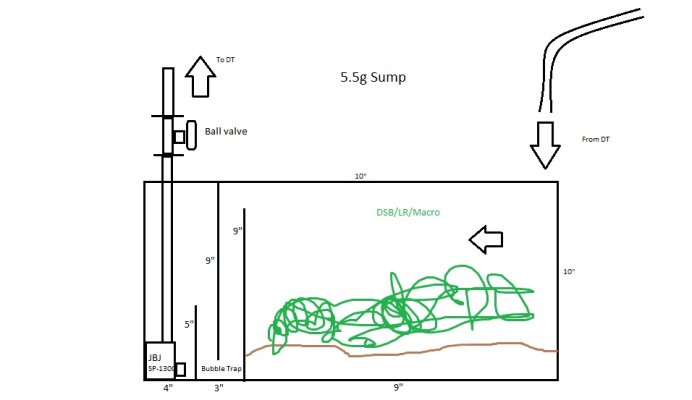

This is where it gets tricky for me..I know sumps are compartmentalized into 3 different compartments, and then there will be a return pump to return the water into the main tank. I do not, although, understand the details behind how this needs to be done.

So far my plan is to get the 5.5g tank from my LFS, then some acrylic from Lowes. I know I have to cut the acrylic to the dept and width of the tank, but what should the height be? Does it matter?

My configuration would be compartment 1 for a protein skimmer/mechanical filtration, compartment 2 for a fuge/biological filtration, and 3 just for return. Do the acrylic panels have to be different heights, or bent to fit an upside down "L"? What kind of tubing would I used for the return? The pump I plan to use is a 250gph JBJ SP-1300.

Any and all help would be greatly appreciated...

Thanks,

- Vic

I do have a few questions since I've never done anything like this.. First, I need an overflow. I cannot drill my tank anymore as it is already filled. My LFS sells overflow boxes for $30 and they seem to work fine as they have some on their tanks. I know the overflow will siphon-feed water from the main tank down into the sump.

This is where it gets tricky for me..I know sumps are compartmentalized into 3 different compartments, and then there will be a return pump to return the water into the main tank. I do not, although, understand the details behind how this needs to be done.

So far my plan is to get the 5.5g tank from my LFS, then some acrylic from Lowes. I know I have to cut the acrylic to the dept and width of the tank, but what should the height be? Does it matter?

My configuration would be compartment 1 for a protein skimmer/mechanical filtration, compartment 2 for a fuge/biological filtration, and 3 just for return. Do the acrylic panels have to be different heights, or bent to fit an upside down "L"? What kind of tubing would I used for the return? The pump I plan to use is a 250gph JBJ SP-1300.

Any and all help would be greatly appreciated...

Thanks,

- Vic