Jimothy

Aquarium Advice Regular

I am trying to select a waterpump, the Mag Drive seems to be the brand I want though I have no idea how powerful a pump to buy.

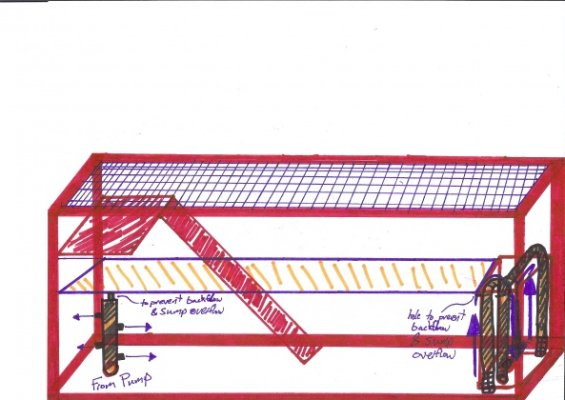

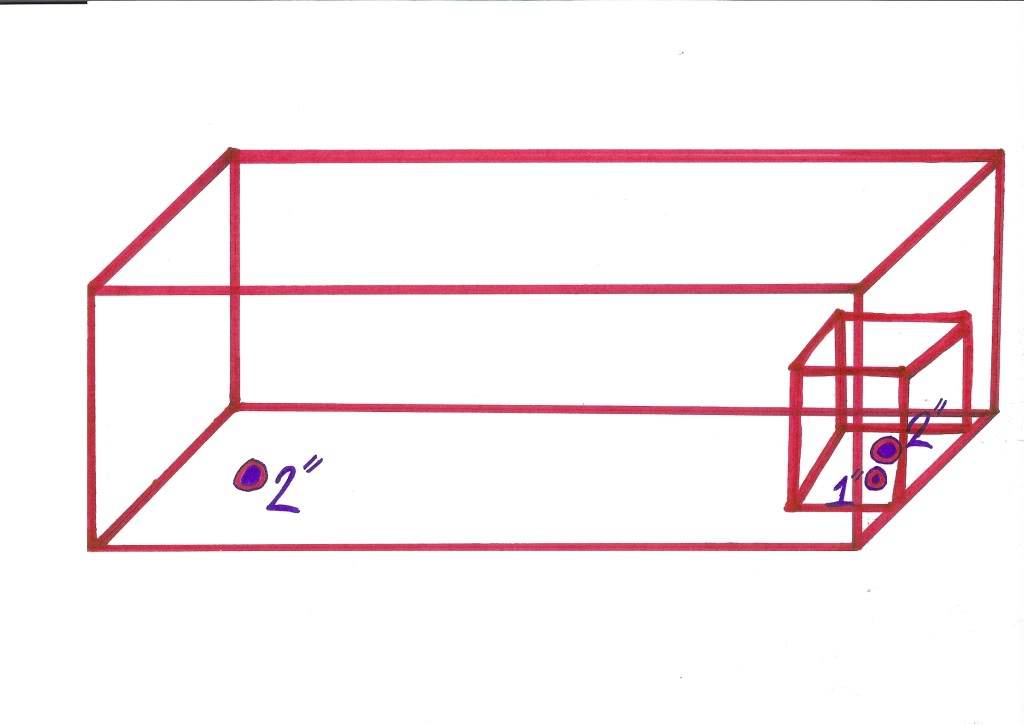

My return will be vertical, and I have read about head loss and pipe length, though the return system I am building will have 4 or more holes set in different directions on a vertical column, and a 1/8" plastic tube just below the surface to break a reverse-flow siphon when the power goes out.

Should I go with the MagDrive 24 and use a ball-valve to reduce the flow, or is that far too powerful for a partiallyfull 180g tank and 65g sump?

My return will be vertical, and I have read about head loss and pipe length, though the return system I am building will have 4 or more holes set in different directions on a vertical column, and a 1/8" plastic tube just below the surface to break a reverse-flow siphon when the power goes out.

Should I go with the MagDrive 24 and use a ball-valve to reduce the flow, or is that far too powerful for a partiallyfull 180g tank and 65g sump?