J.Mcpeak

Aquarium Advice Addict

No, I don't have glass work experience. Nor do I need glass experience to see the potential problems that arise from trying to patch a crack rather than replace the pane of glass.

You said it yourself that the cracked glass you patched was toast with a mosaic of cracks running through it.

My point is, that even if the chance of the bottom panel breaking is minute, the $200 ish dollars that it will cost you to buy a new panel of glass and replace it is miniscule compared to what could happen IF that failure were to happen.

Even assuming all repairs would be diy the damage to your house could EASILY cost thousands of dollars in damage.

There was a person on this forum that bought a cheap stand that got wet and failed dumping a 55g tank on the floor. If i remember correctly the repair bill was over $10,000.

The risk of patching outweighs the benefit.

I think you do need experience of glass and it's working methods to be boldly stating such things.

I have already agreed it would be best to replace the pane and not have a patch so that is a mute point.

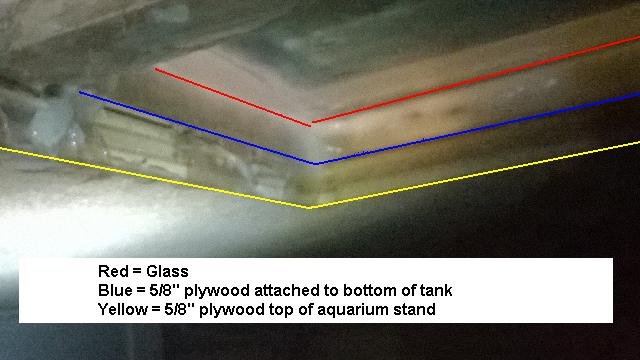

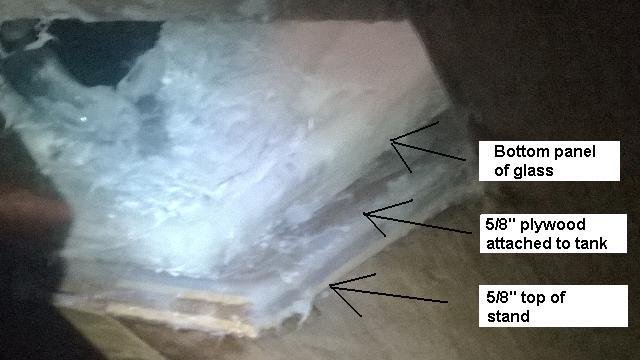

On my tank.

Yes, the panel cracked but the glass spec was sufficent that it held up and no water was lost, one of four panes failed. No problem. (Laminated is 2 sheets normally, similar to front window glass in a car)

For the post,

The bottom panel that exists will most likely crack, as I noted by experience.

The replacement panel, this will cover completely the failed piece making the tank water tight.

There will be no problem except the glass falling from the bottom when the tank is moved, remember I said tape the base panel, standard practice that will prevent the panel separating while it is being moved.

It will be safe, uniform cross hatch at about 6-8" interval with gaffer type tape.

Then fit panel as advised. It will be safe, if you are confident with silicone it should not leak, providing tank is properly installed, level etc.

It really is straightforward.

I also said it would be best to remove the panel but it is not necessary.

A full sheet or two halves, silicone inside without removing the original piece.

Water tight.

Tape base panel for safety, to prevent injury to persons during transit.

Safe, secure.

What is the issue exactly?

You are more likely to have an o ring fail in the future spilling all that water than the silicone failing, or the glass repair, bearing in mind it is a full replacement.

Just cut time. It's exactly the way I'd do things.

You run more risk cracking side panels during deconstruction and properly remounting the glass to make a full repair.

If the base panel really concerns you and you don't like the gaffer tape look, use sticky back window film, secure anti entry type.

That will most certainly provide a safe and viable method for repair.

It will also be cheaper faster and just as safe long term despite the obvious failure in the sheet.

Have you filled them yet or is the niece still giving you "a talking to"

Have you filled them yet or is the niece still giving you "a talking to"