Oliver_Klosoff

Aquarium Advice Apprentice

Hey guys and gals.

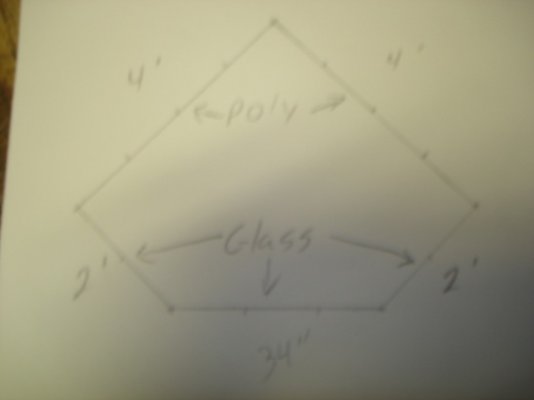

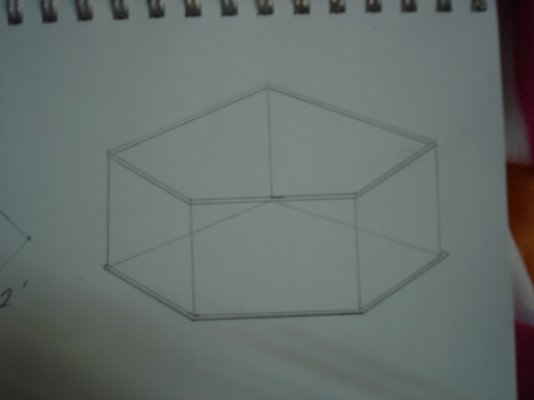

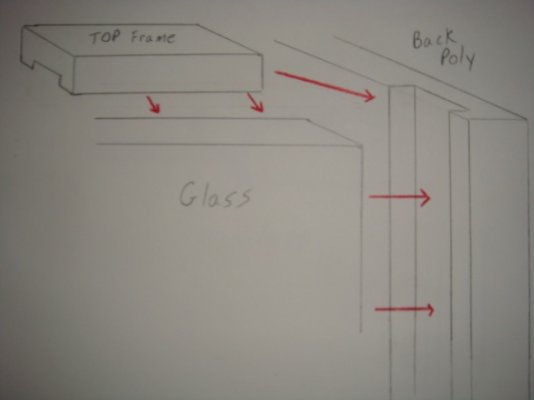

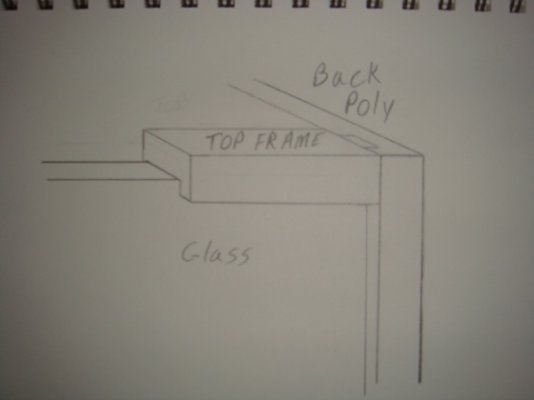

Down the road (along way down the road) I want to build a poly tank with a bay window like front. I am not worried about the poly I have a lot of experience with welding poly tanks for fire trucks but I have never tried to join it with glass. The tank drawings are below. I am mostly worried about the 45° angle joints in the glass up front. I know there are angled joints in octagonal tanks but I have never seen one over 30-40g and this tank will be 200g +. The glass will be ½" thick and came from a old 120g tank. Any toughts I would be happy to hear them.

Thank you Wayne

Down the road (along way down the road) I want to build a poly tank with a bay window like front. I am not worried about the poly I have a lot of experience with welding poly tanks for fire trucks but I have never tried to join it with glass. The tank drawings are below. I am mostly worried about the 45° angle joints in the glass up front. I know there are angled joints in octagonal tanks but I have never seen one over 30-40g and this tank will be 200g +. The glass will be ½" thick and came from a old 120g tank. Any toughts I would be happy to hear them.

Thank you Wayne