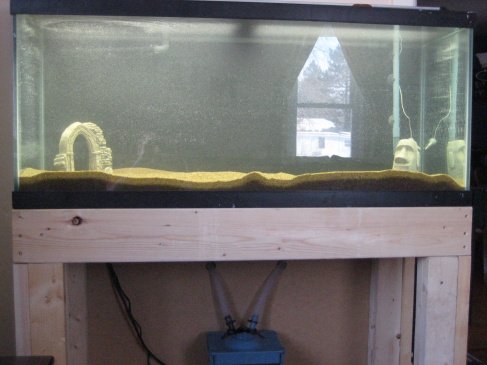

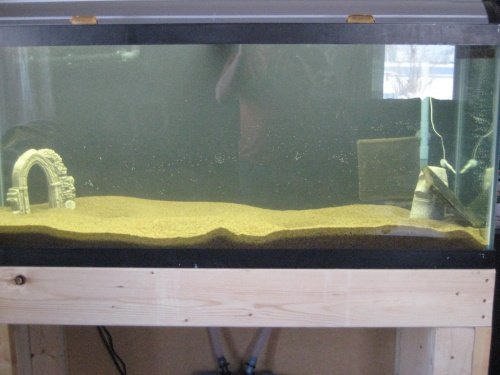

The extra length on the left side of my stand was designed to allow my two cats to have a place where they can sit and look at the fish. But the fish are pretty much old news to them now, so they mostly use that area to look out the nearby window...oh well, I tried! I recently discovered that the extra length is exactly the right dimension to allow me to put a 120 gallon tank on this stand at some point in the future...sort of an unexpected bonus. I will need to add extra support under the shelf...either a pair of heavy legs, or an extension of the cabinet and another door.

I was going for a rustic, old-fashioned look. Hence the knots and grain, and wrought iron hinges and handles. I live in an older house, and have some antiques...so I wanted a stand that would blend. I may have gone too far though...someone told my roommate that it looks like something from an old English pub! Oops. The stand is about 6 years old, and the matching top was made last year. The top opens both from the front (for feeding) and from the top (for cleaning).

I might suggest that you replace the 1/4 inch material on the back with something else. I know the pegboard material that you are talking about...sort of a compressed fiber product, right? I do not think it will add much at all to the structural stability of the stand. As I said before, the lumber of the structure will support the weight straight up and down, but any side to side movement will be a disaster. A solid piece on the back, or a diagonal brace, will prevent any lateral movement and add a large degree of safety and solidity. You may never need the extra strength, but if you do and don't have it...well, get ready for a mess! Yes, the maple coverings may add some extra stability, but mostly on the sides. Unless you are planning on a solid front? No doors? A solid front would do the same as a solid back, but most people like doors on the front.

I look forward to seeing pics of the final result. (I really need to get a router someday...)