[FONT="]

Planning your Algae Scrubber[/FONT]

[FONT="] [/FONT]

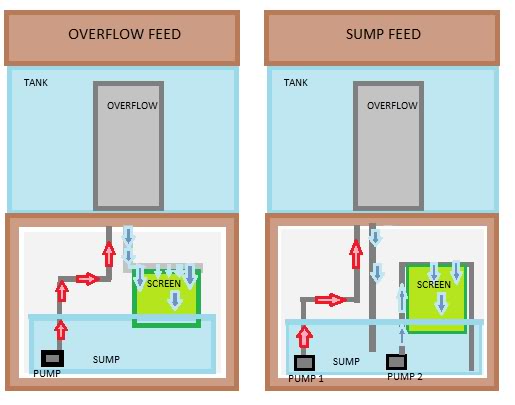

[FONT="]There are 2 basic ways of supplying flow to an Algae Scrubber: directly from the overflow, or from a dedicated pump.[/FONT]

[FONT="] [/FONT]

[FONT="]

[/FONT]

[FONT="] [/FONT]

[FONT="]The above diagram does not illustrate the top-of-tank Algae Scrubber, which would apply to someone running a sumpless system, however this is just a modification of the pump-driven Algae Scrubber with the pump in the display tank.[/FONT]

[FONT="] [/FONT]

[FONT="]The very first step you need to do before buying, measuring, or sketching up anything, is to decide how you are going to supply your Algae Scrubber, and determine what your available flow rate is.[/FONT]

[FONT="] [/FONT]

[FONT="]

Available Flow[/FONT]

[FONT="] [/FONT]

[FONT="]In any case, you need to measure the flow rate.

Do this step. It is critical. Do not, I repeat,

do not calculate the flow rate based on pump curves and head-feet of pressure. This may sound like a total pain in the behind, but just trust me on this one. Would you rather go through all the effort of building an Algae Scrubber, only to have problems and find out that you didn't have as much flow as you thought you did? Believe me, I've been there.[/FONT]

[FONT="] [/FONT]

[FONT="]If you've been reading this thread, you will see that at some point I started making a big deal about this. The reason is that it is a big deal and I think many people don't realize that their pump does not pump at the rated flow, and in the majority of cases, it doesn't come close to the flow calculated by using a standard head-foot calculator program or table. So I have chosen to make it the #1 priority for an Algae Scrubber design, hands down.

You have to know your actual flow.[/FONT]

[FONT="] [/FONT]

[FONT="]For a drain fed Algae Scrubber, fill a pitcher with the water entering the sump. You will probably need to rig up a temporary pipe or routing configuration so that you can fill the container. For a pump-fed Algae Scrubber, set up the pump in a sink filled with water to the same level as your pump will be submerged, and connect the tubing required to reach the height of the connection to the horizontal slot tube, so that you mimic as best as possible the actual conditions. Backpressure created by the slot/screen is negligible unless your flow rate significantly exceeds 35 GPH per inch of slot length.[/FONT]

[FONT="] [/FONT]

[FONT="]Now that you've done all this, fill the container and record the time it takes to fill it. Do this at least a dozen times. The way I do this is by using a recording device, like a digital voice recorder, and just calling out "Go" and "Stop", then afterward, playing it back and using a stopwatch to get the time intervals. You could also have someone else run the stopwatch and write down the times. Average out the times and then figure out how many gallons per hour of flow you are actually getting. If you have multiple drains, measure and extrapolate GPH for each individually, and then add together.[/FONT]

[FONT="] [/FONT]

[FONT="]For instance, if you are using a 1/2 gallon pitcher, and it takes 4.5 seconds to fill it, then you would have (0.5 gallons / 4.5 seconds) x (3600 seconds / 1 hour) which would be 400 GPH.[/FONT]

[FONT="] [/FONT]

[FONT="]Don't be surprised if you have a lot less flow from your pump than you thought you had. I had less than 1/2 of what I thought it was. Head-feet calculations are usually way off, because most people don't use big enough return hose or have other restrictions in the plumbing. Some of it is inherent to reef-ready aquarium design (1" drain, 3/4" return, Danner Mag-Drive 9.5 and larger pumps need 1.5" return, see a problem?). So don't feel bad. A lot of people are in your situation, but they just don't know it.[/FONT]

[FONT="] [/FONT]

[FONT="]

Start with a clean pump. If your pump is not clean, soak it in vinegar for 15 minutes and scrub it good. After running an Algae Scrubber for about 4-5 months, your pump flow will drop about 15%, and by 6 months, it will have dropped by

25%, so you want to know your best-case flow and build around that. It's a lot easier to start with a throttled-back clean pump and open it a little when the flow rate decreases. Figure out your system flow rate, multiply by 80%, and that will be a good starting point. But, it's not going to kill you to start at full flow, and end up with a little less over time. You might just want to clean your pump a little more often, say every 3 months. So it's up to you. Just being aware of your system conditions puts you miles ahead.[/FONT]

[FONT="] [/FONT]

[FONT="]

Big Basic Change #1 - Screen Size[/FONT]

[FONT="] [/FONT]

[FONT="]Originally, the standard method used to calculate the screen size required was based on the size of the tank. Around September 2011, that method was revised to be based on feeding amount. This is a very important change, because not only does it mean an Algae Scrubber screen is more appropriately sized, it also means you will get better growth results. As it turns out, bigger is not necessarily better when it comes to your algae screen – the algae on a screen that is too large compared to the amount being fed will become nutrient deficient over time as the algae will want to grow across the entire screen. Concentrating this algae growth down to the appropriate size in accordance with the amount fed means you will typically get more green growth, and green hair algae is what filters the best (and smells the least, I might add).[/FONT]

[FONT="] [/FONT]

[FONT="]The good news here is that this means that in most cases, you can get away with a significantly smaller screen, and guesstimating your bio-load specific to your system is completely unnecessary.[/FONT]

[FONT="] [/FONT]

[FONT="]Once you figure out your available flow, then it's time to figure out your optimal screen dimensions.[/FONT]

[FONT="] [/FONT]

[FONT="]There are 2 ways of looking at this: square inches based on length and width

dimension, and square inches based on

illuminated surface area. The latter is technically more accurate, but since most people light both sides, the

former is usually referenced.[/FONT]

[FONT="] [/FONT]

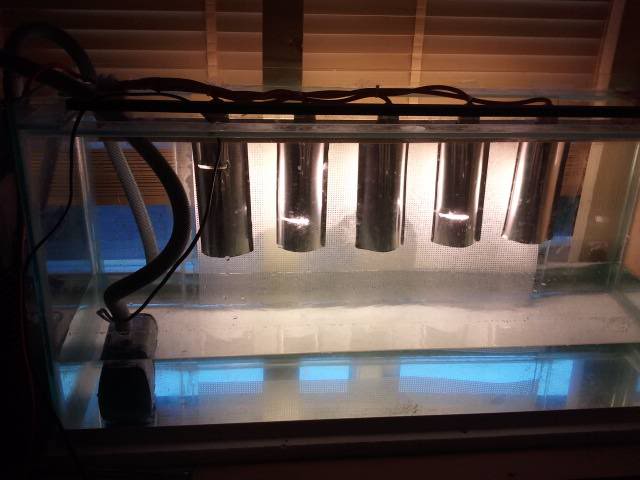

[FONT="]The new rule is based on cube-equivalent amount of food fed daily, regardless of how many gallons you have in the system. You need 12 square inches of screen illuminated on BOTH SIDES with a total of 12 watts of fluorescent light for 18 hours/day for each cube-equivalent fed into the system per day. That means 6 watts per side of real wattage, not equivalent wattage. LED wattage is addressed separately as it has a different set of rules.[/FONT]

[FONT="] [/FONT]

[FONT="]The cube-equivalent is defined as any

ONE of the following:[/FONT]

[FONT="] [/FONT]

[FONT="]1 frozen cube

10 pinches of flake food

10 square inches (60 sq cm) of nori

0.1 dry ounce (2.8 grams) of pellet food[/FONT]

[FONT="]3.25 mL of liquid coral food[/FONT]

[FONT="] [/FONT]

[FONT="]If you feed something else and are having a hard time determining the cube-equivalent, then take the daily amount of food, put it in a blender with some water and puree it well, then strain it using a coffee filter (or a rotifer sieve if you happen to have a spare one laying around) and pour the food into an empty Ocean Nutrition or other cube-type food tray, and you will have the cube-equivalent for that amount of food.

[/FONT]

[FONT="]If you light the screen from only one side, double the dimensional measurement of the screen; light requirement is the same, it’s just all on one side.[/FONT]

[FONT="] [/FONT]

[FONT="]For a non-vertical screen, double the dimensional measurement again. Any screen that is not 100% vertical is treated as a horizontal screen (even if it’s only slightly slanted). This is because of the channeling properties inherent to a slanted or horizontal screen; there is an immediate loss of efficiency when the screen is non-vertical.[/FONT]

[FONT="] [/FONT]

[FONT="]So, just so we're 100% clear on this:[/FONT]

[FONT="] [/FONT]

[FONT="]

Vertical, lit from both sides:

12 square inches of screen material per cube of food per day, 12 watts of light split between each side.[/FONT]

[FONT="] [/FONT]

[FONT="]

Vertical, lit from only one side:

24 square inches of screen material per cube of food per day, 12 watts of light on one side.[/FONT]

[FONT="] [/FONT]

[FONT="]

Non-vertical:

48 square inches of screen material per cube of food per day. Lighting must increase by a factor of 1.5 (discussed in the lighting section). In this case, a MINIMUM of 18 watts of light is needed, preferably much, much more.[/FONT]