Here is the parts list folks. Most of the parts can be obtained from most electronics supplies store or mail order outfits.

PARTS LIST

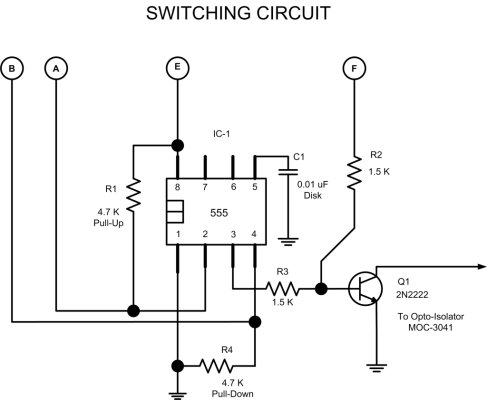

RESISTORS: All ½ watt @ 2%

39 Ohms: R9

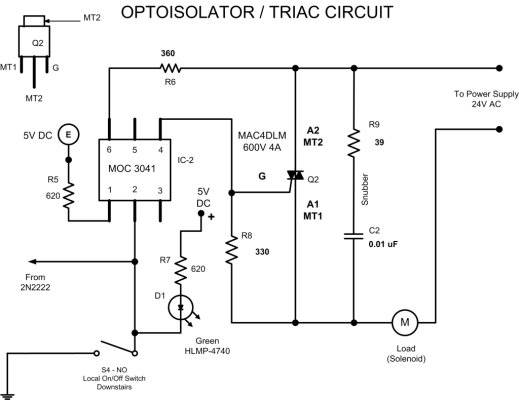

330 Ohms: R8

360 Ohms: R6

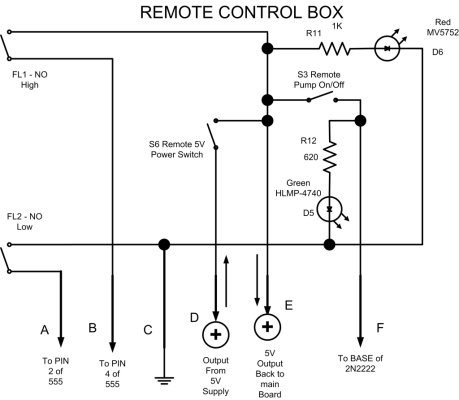

620 Ohms: R5, R7, R12

1 Kilo Ohms: R10, R11

1.5 Kilo Ohms: R2, R3

4.7 Kilo Ohms: R1, R4

CAPACITORS:

C1: 0.01 Microfarad (Disk)

C2: 0.01 Microfarad @ 200 volts (Mylar)

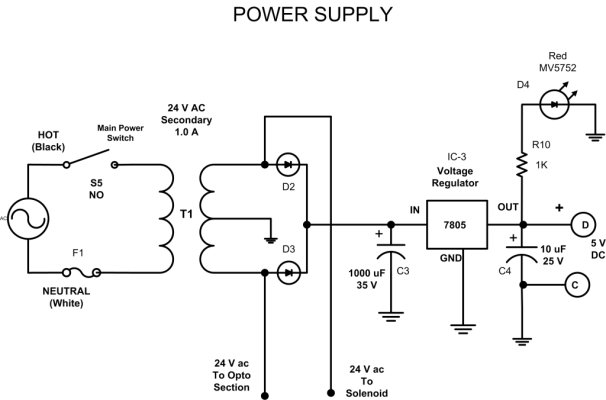

C3: 1000 Microfarads @ 35 volts (Electrolytic)

C4: 10 Microfarads @ 25 volts (Electrolytic)

DISCREET DEVICES:

IC-1: 555 Timer Chip

IC-2: MOC3041 Optoisolator Triac Driver Chip

IC-3: 7805 Voltage Regulator Chip. Rated for 5 volts @ 1 Amp. Case Type: TO-220

Q1: 2N2222 NPN Transistor

Q2: MAC4DLM Triac Chip. Rated for 600 volts @ 4 amps. Case Type: 369D

DIODES/LED:

D1, D5: HLMP4740 Green LED

D4, D6: MV5752 Red LED

D2, D3: Rectifier Diodes. Rated for 125 volts @ 2 amps.

MISCELLANEOUS:

FL1, FL2: Reed Switches – Float Switches Normally Open (

NO) Type

S1, S2, S3, S4: Small Toggle Switches – SPST – Rated for 125 volts @ 2 amps minimum.

T1: Power Transformer – 125V/24 volts CT @ 1 amp.

F1: Fuse – 1.5 amp @ 125 volts

Solenoid: Solenoid Rated 24 volts

AC @ 500 milliamp.

Circuit Boards – Radio Shack Type.

Some Small Wire – Telephone Type Wire

Some Gauge 14 Cable – Power Cord Type

Some Electronics Solder

Some 6 Wire Cable – Telephone Type Wire

Metal Enclosure to House the Main Circuit Boards and Power Supply.

Some Plastic Standoffs to Support and Isolate your Circuit Boards

Electrician Tape

Plastic Enclosure to House your Remote Control Box

Two Wire Quick Connect (4 Required)

Four Wire Quick Connect (2 Required)

Six Wire Quick Connect (4 Required)

8)