sudz

Aquarium Advice Addict

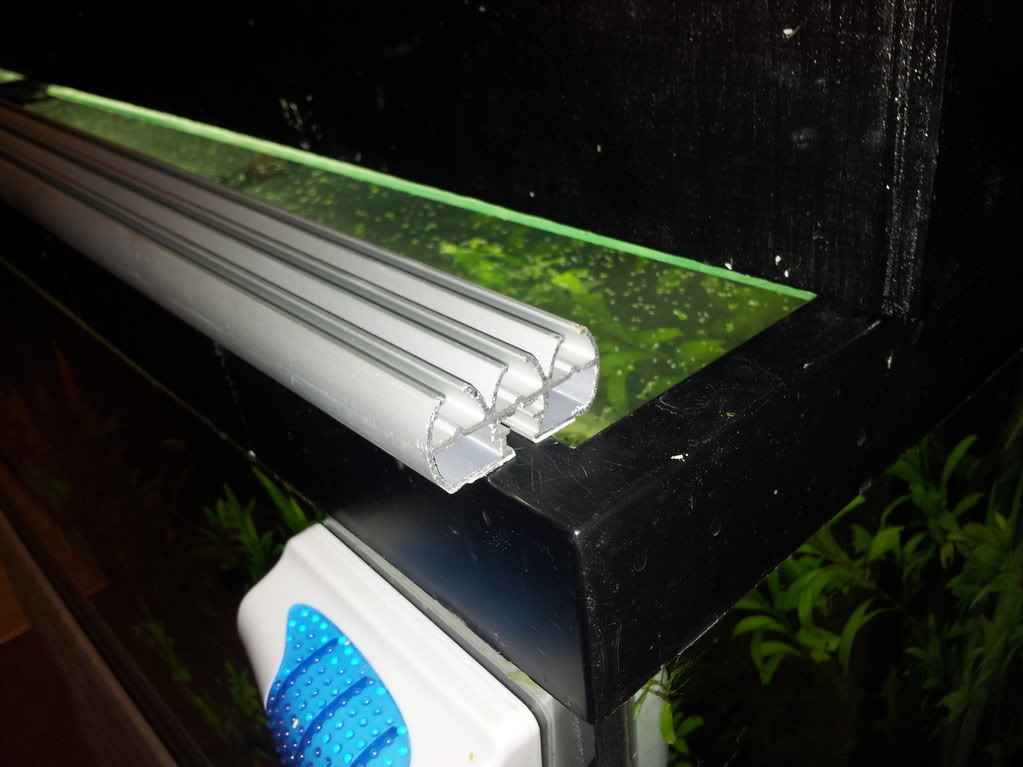

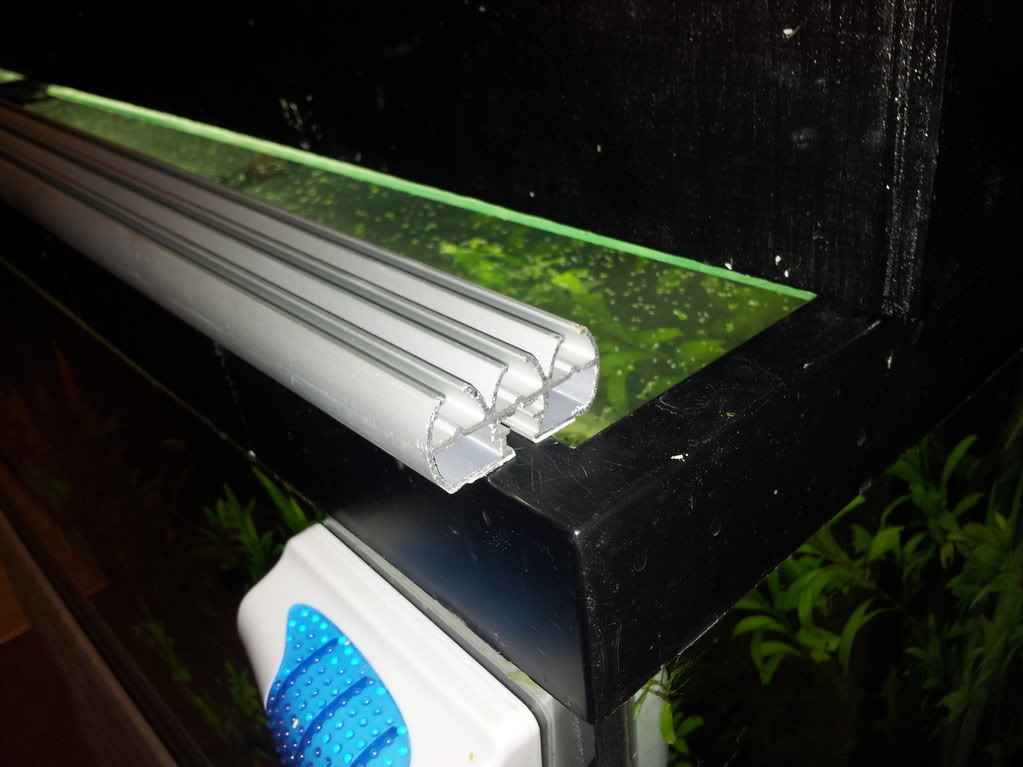

So, Walking the dog, and what do I see... A nice piece of aluminium! I think to my self... Gee... that would make a really nice LED heatsync. I bet its a bunch of pieces.

on my way back, I look at it... and its long and one solid piece!

Heres some pictures:

So, the ONLY flaw is that it's not completely flat on the bottom, but if I stagger the LED's, I'm thinking it'll be perfect to put about 6 LED's to give me the ability to grow some higher light foreground plants.

Its going to be on the cheap, and its going to be mounted inside the cabinet I already have. Do you think with 6 3Watt LED's i'll need active cooling on this sucker?

Also... What are the odds? its 47 inches long. It'll fit PERFECTLY inside my home made cabinet.

Destiny I think. Going to make some LED lighting

on my way back, I look at it... and its long and one solid piece!

Heres some pictures:

So, the ONLY flaw is that it's not completely flat on the bottom, but if I stagger the LED's, I'm thinking it'll be perfect to put about 6 LED's to give me the ability to grow some higher light foreground plants.

Its going to be on the cheap, and its going to be mounted inside the cabinet I already have. Do you think with 6 3Watt LED's i'll need active cooling on this sucker?

Also... What are the odds? its 47 inches long. It'll fit PERFECTLY inside my home made cabinet.

Destiny I think. Going to make some LED lighting