never heard the term filter sock. i'll get ta googlin! Ty for the input.

So you think the second idea is good? no need for baffles just to catch debris or anything?

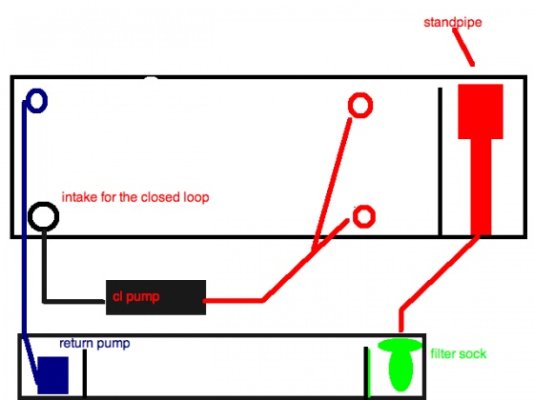

My idea is to put a nice closed loop in this system to move the water, as I do not want ANY plumbing, tubing or anything really, to show inside the tank. No powerheads, etc.

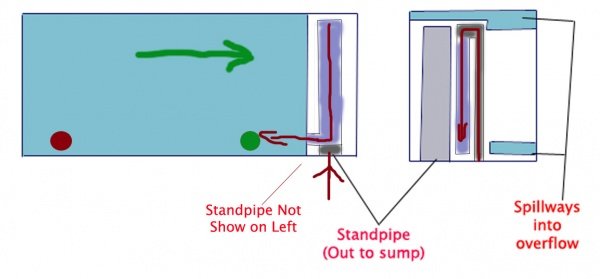

anyway, my point was that I would try to move water in the direction of the OF spillways, however, I cannot really think of a way to do this.

Here's my next dilemma:

Can I return water from the Sump, back onto the same side as the OF spillways and still get enough circulation and flow to push debris into the spillways and thus, into the OF box? (The reason for wanting to return to the same side, is so i can hide the return pipe in the OF compartment.)

I am assuming no, and thus would need some more water movement, hence the closed loop. However to avoid the plumbing being viewable from anywhere I would have to install the closed loop on the back of the tank spraying in from the back. Will that generate enough water flow to move debris from left to right? I don't understand much about water movement and how it effects a tank, but I do know that I want the debris to be moved right to those spillways.

I guess I could put another compartment on the other side and just put powerheads behind that or something similar to blow directly across to the spillways, but that's awfully cumbersome and involved. I am hoping that a closed loop installed on the back will circulate enough current to push those nasties into the OF.

So you think the second idea is good? no need for baffles just to catch debris or anything?

My idea is to put a nice closed loop in this system to move the water, as I do not want ANY plumbing, tubing or anything really, to show inside the tank. No powerheads, etc.

anyway, my point was that I would try to move water in the direction of the OF spillways, however, I cannot really think of a way to do this.

Here's my next dilemma:

Can I return water from the Sump, back onto the same side as the OF spillways and still get enough circulation and flow to push debris into the spillways and thus, into the OF box? (The reason for wanting to return to the same side, is so i can hide the return pipe in the OF compartment.)

I am assuming no, and thus would need some more water movement, hence the closed loop. However to avoid the plumbing being viewable from anywhere I would have to install the closed loop on the back of the tank spraying in from the back. Will that generate enough water flow to move debris from left to right? I don't understand much about water movement and how it effects a tank, but I do know that I want the debris to be moved right to those spillways.

I guess I could put another compartment on the other side and just put powerheads behind that or something similar to blow directly across to the spillways, but that's awfully cumbersome and involved. I am hoping that a closed loop installed on the back will circulate enough current to push those nasties into the OF.