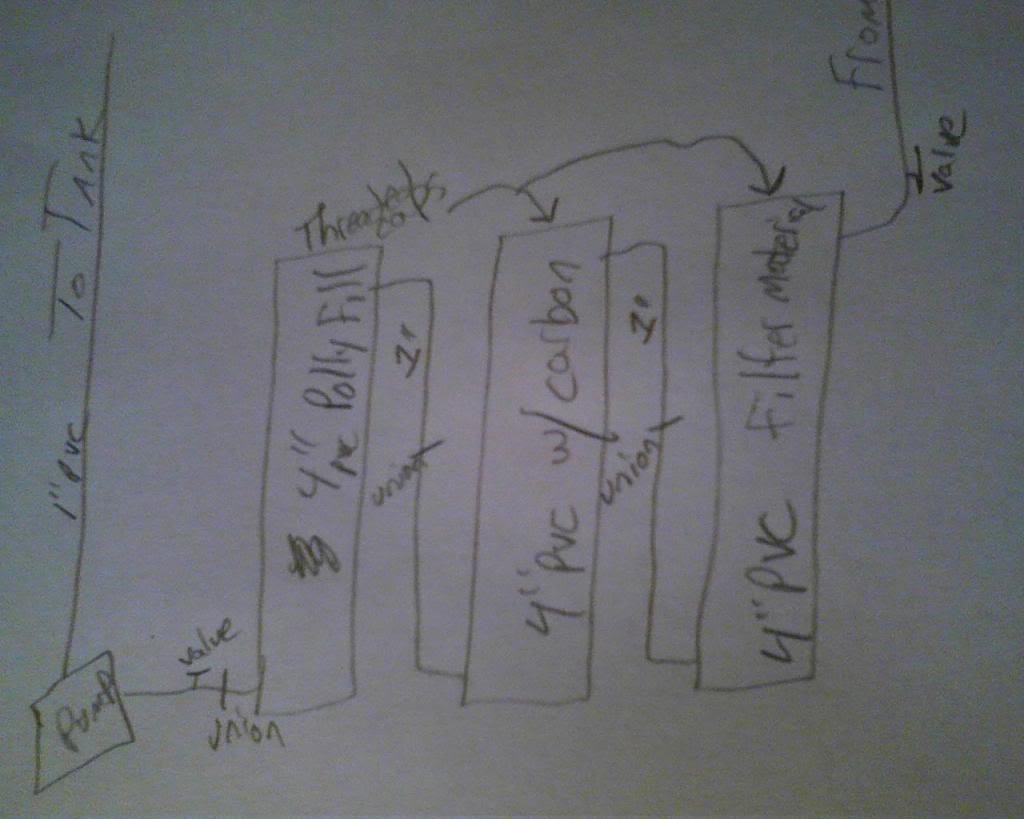

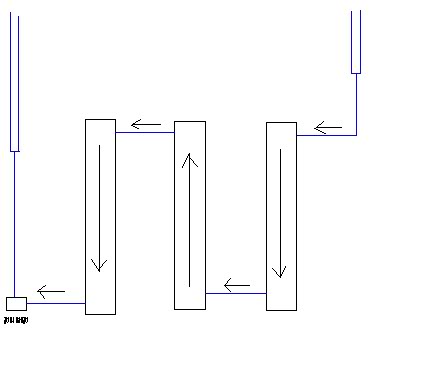

think this one will work? how big a tank do you think it will filter efficiently, what if I up'd it to 6",8"10". cost not a problem, i do plumbing and have the pipe lying around. If I did an *" one, say 3 FT long you think it would do a 75 gallon?

http://www.aquaticplantcentral.com/.../62265-diy-pvc-pipe-canister-filter-step.html

http://www.aquaticplantcentral.com/.../62265-diy-pvc-pipe-canister-filter-step.html