mrbee2828

Aquarium Advice FINatic

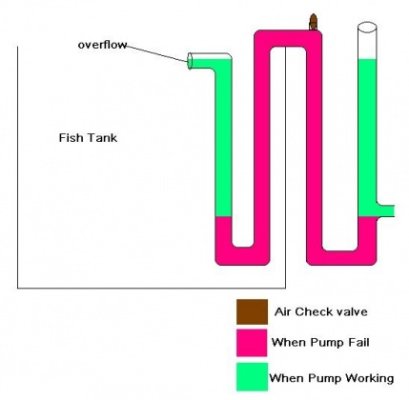

So is the fact that the water is falling about 10" into the overflow "box" causing the bubbles? If those bubbles weren't forming then there would be less air in the pipe which would reduce noise and increase flow... I would think.