Grizz

Aquarium Advice Addict

Carey How thick is the glass? I have a wp40 on 15mm. (9/16in.) thick glass with no problems

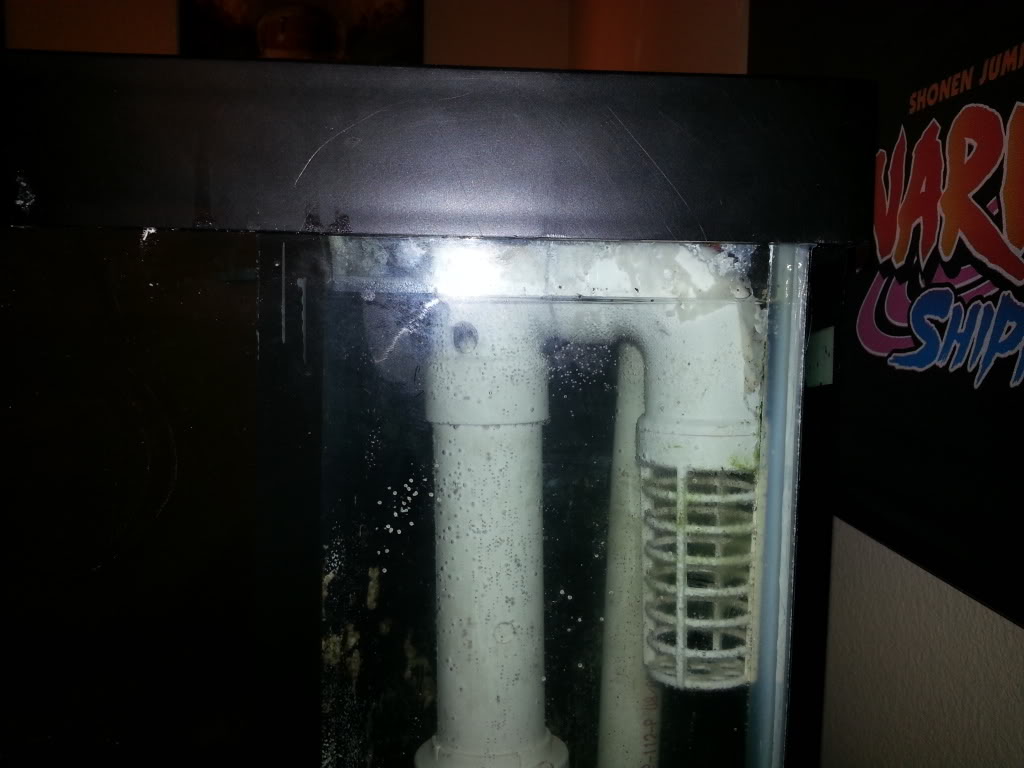

I got something like that, but all clear, on eBay. I have it on my vertical pipe coming off the return pump. I figure that way, when power stops, the pressure of the water coming down will close it. No spring needed that way. Clear is good because you can see if its getting nasty over time plus, the end caps unscrew so it can be cleaned.