Idaho-Tank

Aquarium Advice Activist

Jimbo7,

Since you are at work... Here is what I hope to copy.. ambitious I know...

Since you are at work... Here is what I hope to copy.. ambitious I know...

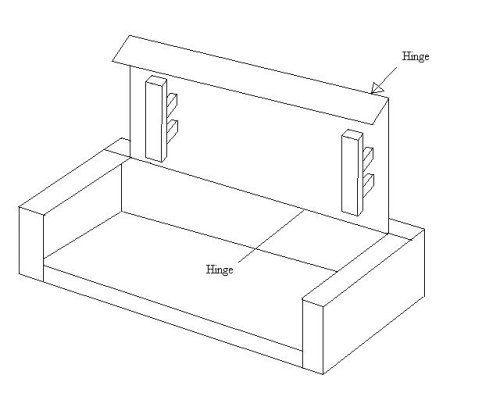

If you are going to build a canopy for your tank anyway i would skip the fixture and go for retrofit lights. As for your canopy and idea so it isn't a pain i drew up a picture because it will be better then trying to explain.I just don't want to spend that kind of money on lighting for a FO tank. I may decide to go reef in the future so getting some fixtures I could add to would be ideal. I like the idea of a nice clean fixture like this since it can just lay on the tank and be concealed with the hood I will build. Any recommendations on fixtures?

I'm pretty sure that the weld-on that melevsreef used is sold any where that acrylic is sold. If that's the cement that you're talking about

It's a sweet looking sump, I need to get back to melevs to check out all his new stuff. Not completely sure how it works though.. where does the tank overflow drain to? if its that overflow box there..how does water get out of the skimmer compartment?

Hi, I'm new (March 2010) and started fish only but after learning a little about the corals...well you know.

I looked at your stand, are you sure you have enough support on the corners to keep it from swaying under the weight of your tank? I can't tell from the pictures but it looks like you might have your back 2x4's going through the shelf. If it is, that'll give you some support.

Sorry, I know just enough about construction to make me an idiot

I think the 2x4 thing in the stands is overrated. has anyone EVER bought a stand that was make for there tank that had ANY 2x4's in it. the compression failure force on 1 2x4 at 3 feet is around 1440 lbs I just set up my 120 on a comercial stand buitl out of nothing but 1x

I think the 2x4 thing in the stands is overrated. has anyone EVER bought a stand that was make for there tank that had ANY 2x4's in it. the compression failure force on 1 2x4 at 3 feet is around 1440 lbs I just set up my 120 on a comercial stand buitl out of nothing but 1x

Thinking about this Skimmer... My old one was a pretty cheap one and Id like to replace it with a better one. Any thoughts?

ASM G-3 Protein Skimmer

Coming along very nicely

Coming along very nicely