kribbman

Aquarium Advice Activist

- Joined

- Feb 5, 2008

- Messages

- 139

Hi Everyone!

I have a few questions for you guys and gals today.

First thing is How long does aquarium silicone sealant take to cure?

When is it safe to put in the water?

I built these two "thingys" so that I could check CO2 bubble production from my Yeast canisters and to stop the white filaments from getting into my diffusor. I glued them together yesterday and the insides still smell of silicone. Am I supposed to wait for the smell to clear before I can safely use them? They are connected to an air pump at the moment so air can circulate through them and perhaps cure the silicone faster.

The only problem with them so far is that they are sealed shut so I wont be able to clean them. And I realize I could have done the same thing with a small jar but I was concerned about it being airtight, Has anybody else here used jars or other types of ready made containers?

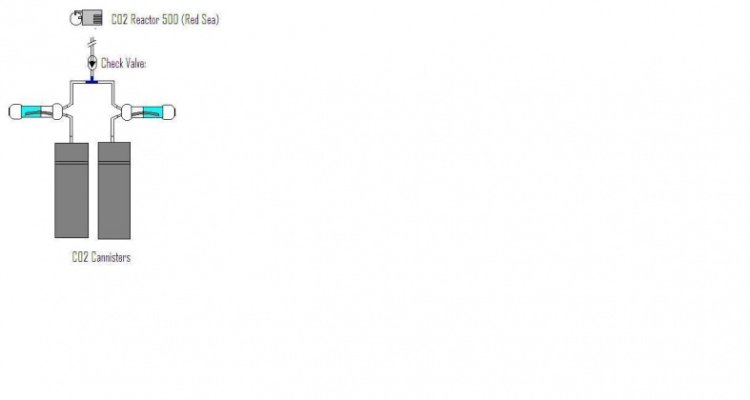

Here's a picture of the bubble counters/water traps.. and a picture of my planed final C02 setup

I have a few questions for you guys and gals today.

First thing is How long does aquarium silicone sealant take to cure?

When is it safe to put in the water?

I built these two "thingys" so that I could check CO2 bubble production from my Yeast canisters and to stop the white filaments from getting into my diffusor. I glued them together yesterday and the insides still smell of silicone. Am I supposed to wait for the smell to clear before I can safely use them? They are connected to an air pump at the moment so air can circulate through them and perhaps cure the silicone faster.

The only problem with them so far is that they are sealed shut so I wont be able to clean them. And I realize I could have done the same thing with a small jar but I was concerned about it being airtight, Has anybody else here used jars or other types of ready made containers?

Here's a picture of the bubble counters/water traps.. and a picture of my planed final C02 setup

Attachments

Last edited: