oxidessc

Aquarium Advice Newbie

right guys, first post on here and its gonna b a interesting 1.

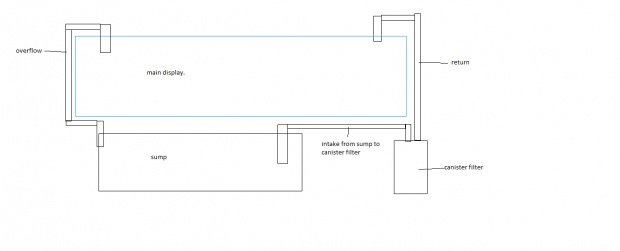

first off my tank is a 28 gallon nano with a few frags in atm. basicly im gonna build a pvc overflow pipe, ive done loads of research into that and thats not the problem. now im just wandering as im running a canister filter at the moment and im trying to do this on the cheap. would it be possiable to have the overflow run to the sump then the original intake from the canister filter taking water in from the sump then pumpin it back to the tank. i already know that the canister filer pump is powerful enough to get the water back to the pump?

its a origional idea (well i havent seen anything like it on forums or vieos on youtube) just wandering peoples thoughts.

thanks. stu.

first off my tank is a 28 gallon nano with a few frags in atm. basicly im gonna build a pvc overflow pipe, ive done loads of research into that and thats not the problem. now im just wandering as im running a canister filter at the moment and im trying to do this on the cheap. would it be possiable to have the overflow run to the sump then the original intake from the canister filter taking water in from the sump then pumpin it back to the tank. i already know that the canister filer pump is powerful enough to get the water back to the pump?

its a origional idea (well i havent seen anything like it on forums or vieos on youtube) just wandering peoples thoughts.

thanks. stu.