Hey everyone. Sorry to make my first post a "help me" question one, but you're my only hope.

I've been interested in building a large plywood tank for years, but always been stumped on the best way to filter it. Now i'm getting serious about this project, and decided it's time to figure out. (freshwater tank btw) My overall goal is simplicity and ease of care for the tank. I think i have a design that will accomplish those goals.

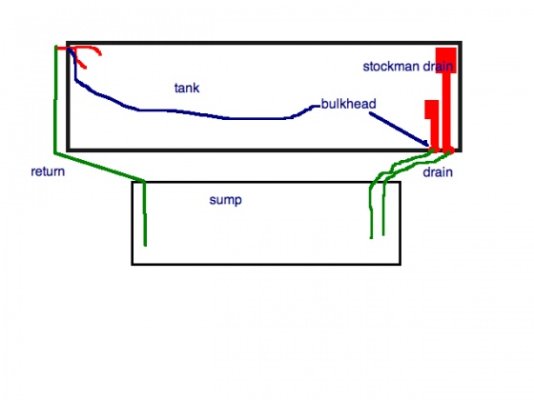

Since this will be a plywood tank from scratch, no worries about drilling, etc. My idea was to make my overflow merely just a large pvc pipe (3in diameter or so) with its top at my desired water level. It will extend through the bottom of the tank, and flow into my sump. I figured there's no reason I couldn't throw some filtration right into that pipe and filter it as it falls into the sump. I saw an article where someone used a bunch of plastic type scrubbing pads in a bucket. Those would be the perfect size in diameter to wedge 10 or so one on top of another down inside my overflow pipe. Maybe add some charcoal somewhere and all in all, it wouldn't slow down water flow too much.

I'd seperate the pump in the sump so it always had just a small portion of water to send back up in case the pipe clogged, the pump couldn't transfer the entire contents of the sump back into the main tank. Running dry would destroy the pump no doubt, but better than 30 gallons all over my floor.

Observe my computer graphics skills in the attachment.

The problems I see with this design are a few. 1) There's no resevoir of water to continuously send water down the pipe if the return pump is not able to somewhat keep up with the intake pvc pipe. What I mean is, if the pump is too slow, the water will go over the sides of the pipe sporadically and not continuously, which will play havok on the filtration i imagine. I've been trying to come up with a way to add a resevoir INSIDE THE PIPE, (ie: a drip tray wedged down about a foot inside the pvp pipe to slow down the flow and build up a resevoir) but I think they might be too risky. A better way would be to make sure I have a powerful pump to return water at a very high rate, but not high enough to overtake the pvc filtration. I think that's relatively doable.

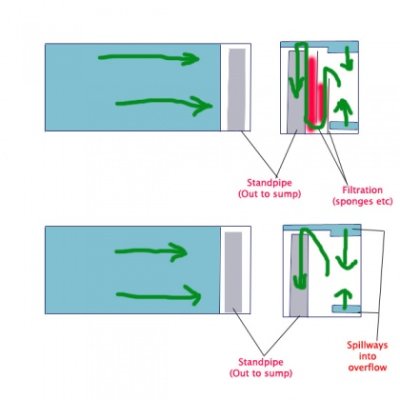

The second problem I have, is that I hate the idea of filtering ONLY surface water. We all know the bottom of the tank is where the nastiest stuff lies. The solid chunks of waste and other nasties that need to go. The only way I can see to deal with this, is with a builtin overflow box with a syphon system and the syphon hoses being at the bottom of the tank. I really feel so strongly about it, that I might ditch my simple inline system for a more complicated 2 compartment blah blah system.

Any feedback is very welcome and will be appreciated wholeheartedly. ANY FEEDBACK at all!

I've been interested in building a large plywood tank for years, but always been stumped on the best way to filter it. Now i'm getting serious about this project, and decided it's time to figure out. (freshwater tank btw) My overall goal is simplicity and ease of care for the tank. I think i have a design that will accomplish those goals.

Since this will be a plywood tank from scratch, no worries about drilling, etc. My idea was to make my overflow merely just a large pvc pipe (3in diameter or so) with its top at my desired water level. It will extend through the bottom of the tank, and flow into my sump. I figured there's no reason I couldn't throw some filtration right into that pipe and filter it as it falls into the sump. I saw an article where someone used a bunch of plastic type scrubbing pads in a bucket. Those would be the perfect size in diameter to wedge 10 or so one on top of another down inside my overflow pipe. Maybe add some charcoal somewhere and all in all, it wouldn't slow down water flow too much.

I'd seperate the pump in the sump so it always had just a small portion of water to send back up in case the pipe clogged, the pump couldn't transfer the entire contents of the sump back into the main tank. Running dry would destroy the pump no doubt, but better than 30 gallons all over my floor.

Observe my computer graphics skills in the attachment.

The problems I see with this design are a few. 1) There's no resevoir of water to continuously send water down the pipe if the return pump is not able to somewhat keep up with the intake pvc pipe. What I mean is, if the pump is too slow, the water will go over the sides of the pipe sporadically and not continuously, which will play havok on the filtration i imagine. I've been trying to come up with a way to add a resevoir INSIDE THE PIPE, (ie: a drip tray wedged down about a foot inside the pvp pipe to slow down the flow and build up a resevoir) but I think they might be too risky. A better way would be to make sure I have a powerful pump to return water at a very high rate, but not high enough to overtake the pvc filtration. I think that's relatively doable.

The second problem I have, is that I hate the idea of filtering ONLY surface water. We all know the bottom of the tank is where the nastiest stuff lies. The solid chunks of waste and other nasties that need to go. The only way I can see to deal with this, is with a builtin overflow box with a syphon system and the syphon hoses being at the bottom of the tank. I really feel so strongly about it, that I might ditch my simple inline system for a more complicated 2 compartment blah blah system.

Any feedback is very welcome and will be appreciated wholeheartedly. ANY FEEDBACK at all!