vundercoverdog

Aquarium Advice Regular

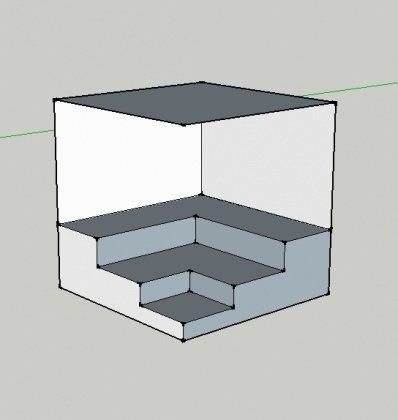

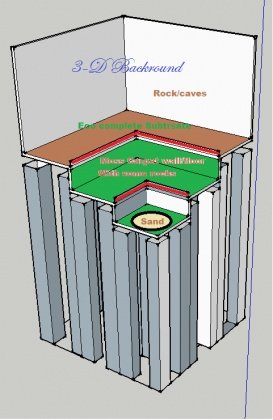

So as you can see it's a complicated design but it artistic and i love designing it and would like to bring it to life.

I thought of starting out with a custom base made of plywood aswell as the back and canopy but the two front viewing panels need to be cut to fit the "stair" base. I thought of tempered glass but can't find a place to cut it for me like that. does anyone know where i can get it cut? (i know you can't cut tempered glass but before it goes the tempering process it could be right?)

Dimensions: 3'x3'x3'

The stand will be 3'x3'x3'

Canopy will be 3'x3'x2'

Any suggestions on how to build the stand? I thought of using 3x4's

Anyone built something similiar to this?

I thought of starting out with a custom base made of plywood aswell as the back and canopy but the two front viewing panels need to be cut to fit the "stair" base. I thought of tempered glass but can't find a place to cut it for me like that. does anyone know where i can get it cut? (i know you can't cut tempered glass but before it goes the tempering process it could be right?)

Dimensions: 3'x3'x3'

The stand will be 3'x3'x3'

Canopy will be 3'x3'x2'

Any suggestions on how to build the stand? I thought of using 3x4's

Anyone built something similiar to this?