I am finally ready to do some plumbing but want to get a game plan first.

The tank is a 65g with an overflow built in but the person I got it from didn't have the bulkheads that go on the bottom piece of glass. There are (2) holes. One is a 1.76" which seems to be for a 1" bulk head and the other is a 1.48" which seems to be for a 3/4" bulk head. I was told the 1" bulk head should be good for about 600gph correct?

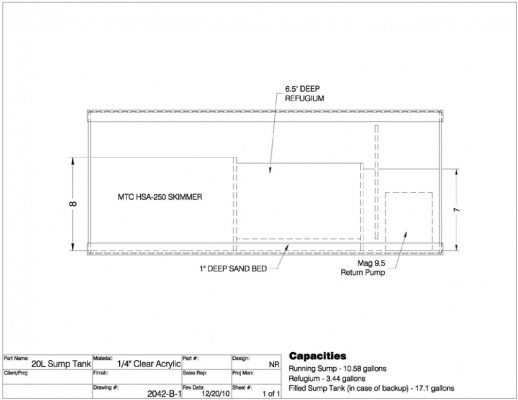

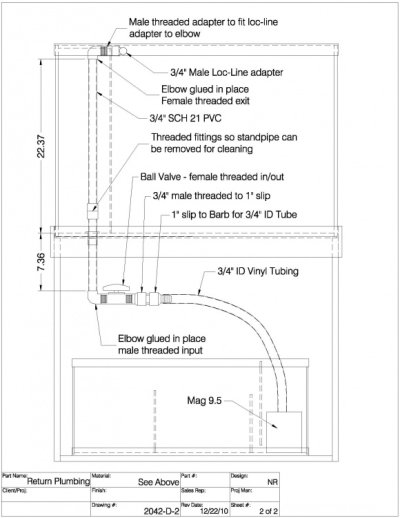

My question is, can I get the plumbing parts from Lowe's for this setup? Mainly something to use for bulkheads? I am using an MTC HSA-250 skimmer that will be sitting in a 20g breeder tank I'm adding baffles to. I'd like to run hard lines to as much as possible. I have a Mag 7 for the return pump which should be able to do around 425gph with the 48" head height. Should I try and get closer to 600gph? I have a Mag 9.5 but was told that would be best used on the skimmer. I'd like to go ahead and make one of the Durso standpipes. Those look like a nice edition to have.

I'd also like to maybe have the exit of the return line in the top of the tank have 2 outputs? I think that should be pretty easy but it should make for some better circulation in the tank?

Any and all suggestions and opinions are welcome! I'm very new to all this and trying to absorb as much info as possible. I'll most like have some basic drawings tomorrow sketched up of what I plan on doing that I can post to make things a bit clearer.

The tank is a 65g with an overflow built in but the person I got it from didn't have the bulkheads that go on the bottom piece of glass. There are (2) holes. One is a 1.76" which seems to be for a 1" bulk head and the other is a 1.48" which seems to be for a 3/4" bulk head. I was told the 1" bulk head should be good for about 600gph correct?

My question is, can I get the plumbing parts from Lowe's for this setup? Mainly something to use for bulkheads? I am using an MTC HSA-250 skimmer that will be sitting in a 20g breeder tank I'm adding baffles to. I'd like to run hard lines to as much as possible. I have a Mag 7 for the return pump which should be able to do around 425gph with the 48" head height. Should I try and get closer to 600gph? I have a Mag 9.5 but was told that would be best used on the skimmer. I'd like to go ahead and make one of the Durso standpipes. Those look like a nice edition to have.

I'd also like to maybe have the exit of the return line in the top of the tank have 2 outputs? I think that should be pretty easy but it should make for some better circulation in the tank?

Any and all suggestions and opinions are welcome! I'm very new to all this and trying to absorb as much info as possible. I'll most like have some basic drawings tomorrow sketched up of what I plan on doing that I can post to make things a bit clearer.