Jonnypro

Aquarium Advice Freak

- Joined

- Mar 26, 2012

- Messages

- 388

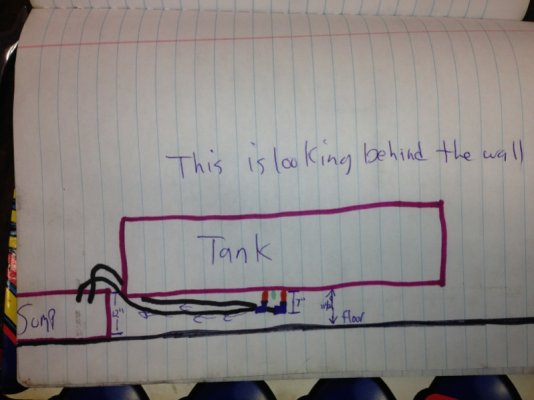

I am putting a 125g salt in my wall. Now the height of the tank from the floor is going to only be at the most 11 1/2". I made a custom refugium. That is 48"x 12"x 12" my plumbing is going to be flex hose and this is how far the overflow plumbing sticks down.

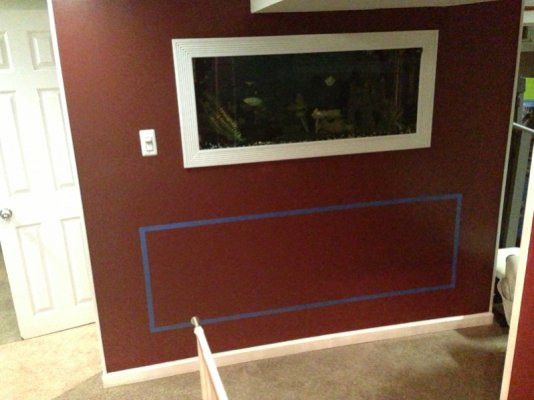

This is My fresh 55g fresh. The salt is going in underneath this tank. I am leaving myself only 1' to do maintenance. I know gravity and the pressure of the water should let me do somewhat of an incline. But how should I plumb this?? I have looked around for stuff like this but found nothing. Lmk

This is My fresh 55g fresh. The salt is going in underneath this tank. I am leaving myself only 1' to do maintenance. I know gravity and the pressure of the water should let me do somewhat of an incline. But how should I plumb this?? I have looked around for stuff like this but found nothing. Lmk