Semperfi2091

Aquarium Advice Newbie

- Joined

- Jan 28, 2017

- Messages

- 8

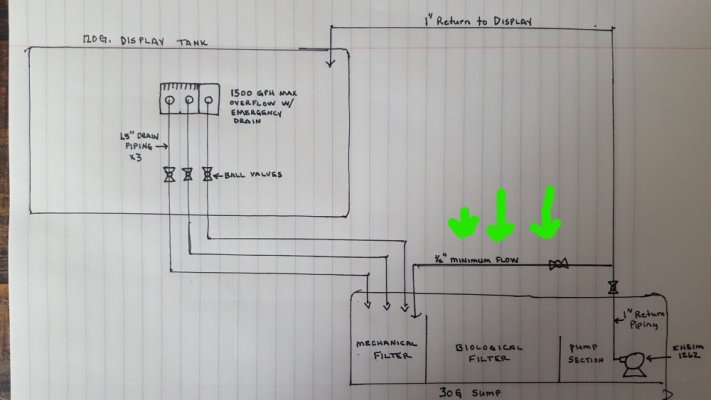

So I'm setting up a 120G cichlid tank and instead of running a couple expensive canister filters I'm building a 30G sump to turn my water over as close to 10x an hour as possible.

Because I work at a chemical plant and I'm so accustomed to not throttling back on the discharge of pumps to help protect their seals and longevity, I'm having a hard time with the idea that the best way to regulate flow back to the display tank is to cut back on the discharge of the pump with a ball valve. Instead, I'm thinking of using what we call a Minimum Flow line back to the first section of my sump. The benefit would be three fold, IMO. First, you are always flowing the pump's design output, just diverting some of the flow to a different spot. Second, you'd be limiting the back pressure you were putting on the pump and further restricting the amount of flow you get back to the display tank. Finally, you'd be constantly running a slip stream of your water back through your sump for a second filtering.

Here's a crude drawing of what I'm considering doing. The arrows point to the minimum flow I'm referring to.

Because I work at a chemical plant and I'm so accustomed to not throttling back on the discharge of pumps to help protect their seals and longevity, I'm having a hard time with the idea that the best way to regulate flow back to the display tank is to cut back on the discharge of the pump with a ball valve. Instead, I'm thinking of using what we call a Minimum Flow line back to the first section of my sump. The benefit would be three fold, IMO. First, you are always flowing the pump's design output, just diverting some of the flow to a different spot. Second, you'd be limiting the back pressure you were putting on the pump and further restricting the amount of flow you get back to the display tank. Finally, you'd be constantly running a slip stream of your water back through your sump for a second filtering.

Here's a crude drawing of what I'm considering doing. The arrows point to the minimum flow I'm referring to.