Floyd R Turbo

Aquarium Advice Addict

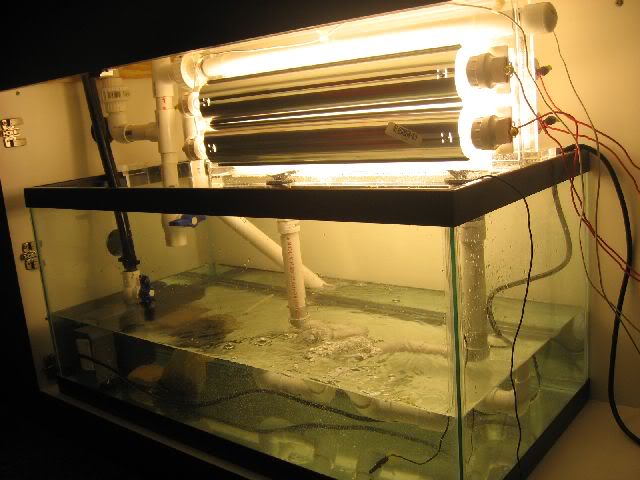

I've got a 125 reef that I maintain here:

http://www.aquariumadvice.com/forums/f11/tank-journal-125-reef-125546.html

It has a Mag 12 pump that was replaced in February and cleaned well 2 weeks ago when I replaced the sump with a 40B. I also moved it to the other end of the sup so it is now directly underneath the bulkhead. It has a vertical head of about 4.5 feet.

This is the spec sheet

http://www.dannermfg.com/instructionsheets/ZG100.PDF

Based on that spec sheet, I should be getting 950-1100 GPH out of this configuration. I am getting about 1/2 gallon every 5 seconds, which works out to less than 400 GPH. What could explain this?

I did notice that on the spec sheet it states that "1-1/2 inch inner diameter is the minimum hose size that should be used for maximum flow". This seems kind of silly, because the output nozzle is made to fit a screw-on adapter for a 1" ID hose (which is what I am using), and I thought that the larger the ID the greater the head pressure would be.

I measured the flow rate by sticking a 1/2 gallon pitcher under the overflow and timing the fill rate about 10 times and averaging the results. Initially it came out to over 5.5 seconds, but after moving/cleaning it dropped to around 5 seconds.

So what am I missing?

EDIT: the bulkhead for the return is also 1"

http://www.aquariumadvice.com/forums/f11/tank-journal-125-reef-125546.html

It has a Mag 12 pump that was replaced in February and cleaned well 2 weeks ago when I replaced the sump with a 40B. I also moved it to the other end of the sup so it is now directly underneath the bulkhead. It has a vertical head of about 4.5 feet.

This is the spec sheet

http://www.dannermfg.com/instructionsheets/ZG100.PDF

Based on that spec sheet, I should be getting 950-1100 GPH out of this configuration. I am getting about 1/2 gallon every 5 seconds, which works out to less than 400 GPH. What could explain this?

I did notice that on the spec sheet it states that "1-1/2 inch inner diameter is the minimum hose size that should be used for maximum flow". This seems kind of silly, because the output nozzle is made to fit a screw-on adapter for a 1" ID hose (which is what I am using), and I thought that the larger the ID the greater the head pressure would be.

I measured the flow rate by sticking a 1/2 gallon pitcher under the overflow and timing the fill rate about 10 times and averaging the results. Initially it came out to over 5.5 seconds, but after moving/cleaning it dropped to around 5 seconds.

So what am I missing?

EDIT: the bulkhead for the return is also 1"