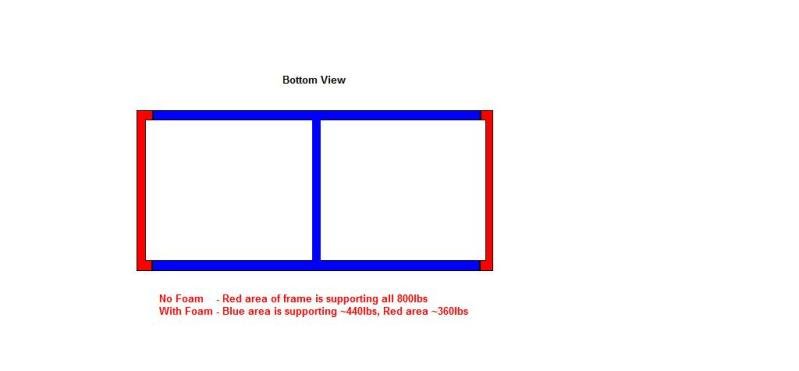

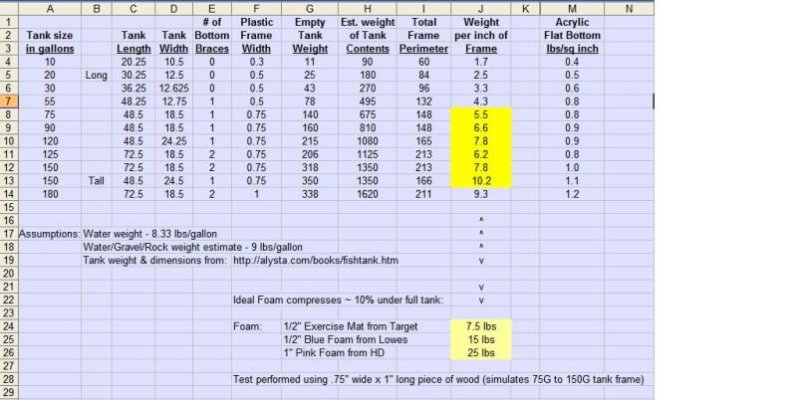

putting soft foam under a tank, is in my view of little use. It will fill the gap, but i don't believe it will offer much in the way of support. The original question, if I read correctly is about the use of rigid foam, one of the various types of styrofoam. Styro will absorb discrepencies in flatness on a stand, whether it be open or solid top. It will not help with leveling. The popular metal stands rarely if ever support the entire bottom edge of the tank. I have yet to see one that doesn't have a gap in the middle somewhwere, including ones I have built, taking great care to use the straightest steel I could find (both angle iron and square tubing). The reality is that if you took a tank and supported the ends only, it would still hold water. The tank would be under a lot of stress, but it would be strong enough to hold together, as long as the 2 supports were in the same plane (ie,level). No one in their right mind would do this of course.

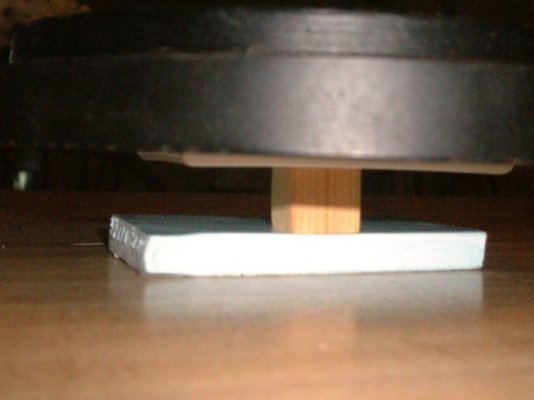

The other extreme is to support the entire bottom. If done correctly, it takes the bottom pane of the aquarium out of the equation as it no longer carries any weight, only holds in the sides. The first all glass aquariums were built locally, when a guy who was using silicone in his work came up with the idea of gluing glass together to make a tank. He was one of the principals who started Crystal aquarium. They established the thicknesses needed for the various sizes of tanks. The first tanks were built without frames and broken bottoms were a problem. This was not because of any inherent weakness in the design, but caused by people setting the tank on a piece of gravel and having the point load created by filling the tank, causing the bottom to fracture. This problem was solved by adding a bottom frame (wooden ones at first) to lift the bottom off the stand or whatever the tank was sitting on. Keep in mind that in the late fifities, there were not the choices of stand types we see today. Most custom tanks are built without any plastic frame on the bottom, and are set on styro tosupport the bottom and provide a cushion to protect the bottom. The styro will compress where there are high spots and the bottom of the tank ends up supported over its entire area if a solid base is used. If the bottom is supported, it is less likely to break if something is dropped on it since glass is very hard and if supported so it can't flex, it won't break. A tank with an unsupported/suspended bottom can be broken with a point load of a rock pressing down on a piece of gravel. Our club president lost 2 tanks to this, and now puts styro under all his rocks.

The often repeated as gospel, "the manufacturer says", the tank should not have the bottom supported is for their protection. They have no control of how we set up our tanks, so they build a stand that eliminates some of the dangers caused by improper tank placement. It may not be the best, but is a compromise that is in their best interest. The suspended bottom that fits inside the sides rather than beneath them that some manufacturers use addresses the liklihood of the tank being placed on an eneven surface, or a stand that sags over time. This design allows for a little more flex, but isn't as strong as side on bottom. The silicone is expected to carry the weight of the load in the tank, as well as hold the sides in. Would you build a stand this way where only the fasteners carried all the weight? Not likely, as most will put the legs under the weight rather than beside it.

So, I will continue to use styro (white) under my tanks, particularily the 5 I built that have no bottom trim. I have seen the difference it makes, and it is the way industry deals with machinery, where grout is used underneath a machine to support the weight once it is leveled.

I have a pretty successful career of "not understanding physics", so I'm not really too concerned about your suggestion or the fact that you think I'm personally driving tank prices up!

I have a pretty successful career of "not understanding physics", so I'm not really too concerned about your suggestion or the fact that you think I'm personally driving tank prices up!