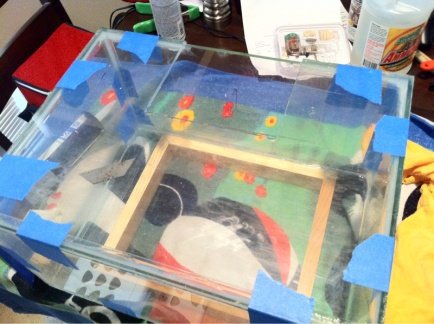

So I'm DIYing a Fluval Edge out of an old 20g tank that I could neither sell nor give away as a gift for my mother.

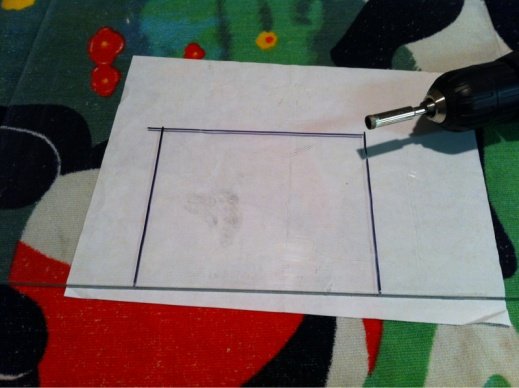

I've got the glass cut to size and mocked up as a cube but I'm trying to determine the best way to notch out the glass for the filter and the lights.

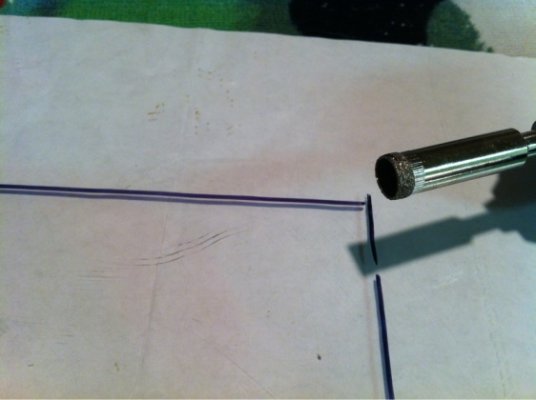

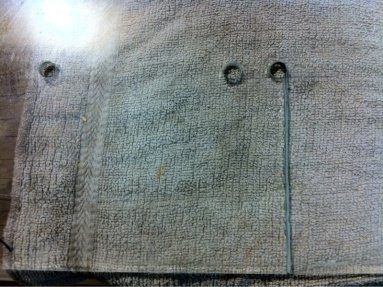

My best guess is to drill holes in what will be the inside corners of the notch and score between the holes and then out to the edge of the glass and try to stress the scores to break evenly.

I've also thought about drilling several holes and just trying to break it out.

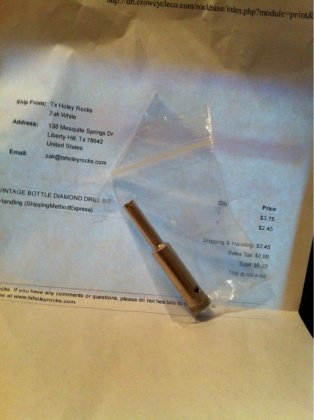

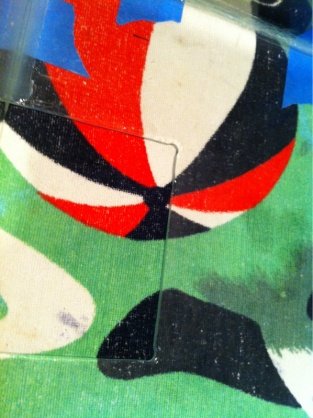

That's the only pic I can find right now of what I'm talking about.

I'll see if I can grab the glass and take some pics of what I need if it's not clear enough.

I've Googled "notching glass" and "cutting glass" and found a few ideas but I figured I'd ask before diving in and breaking the glass.

Since I'm building this out of an old tank, I'm using almost every bit of glass so there's no room for mistakes. I know I can do it myself so I don't want to take it somewhere and have it cut for me.

Thanks in advance.

I've got the glass cut to size and mocked up as a cube but I'm trying to determine the best way to notch out the glass for the filter and the lights.

My best guess is to drill holes in what will be the inside corners of the notch and score between the holes and then out to the edge of the glass and try to stress the scores to break evenly.

I've also thought about drilling several holes and just trying to break it out.

That's the only pic I can find right now of what I'm talking about.

I'll see if I can grab the glass and take some pics of what I need if it's not clear enough.

I've Googled "notching glass" and "cutting glass" and found a few ideas but I figured I'd ask before diving in and breaking the glass.

Since I'm building this out of an old tank, I'm using almost every bit of glass so there's no room for mistakes. I know I can do it myself so I don't want to take it somewhere and have it cut for me.

Thanks in advance.