Jimothy

Aquarium Advice Regular

Yes! Too powerful!

I think that point has drifted aside while I worked on other things. Back to it: whether or not I can return the magdrive24 (waiting to hear back from merchant) or recoup some of its value on craigslist I will need a less powerful pump. For the brand: I am willing to pay more for silence, though I don't know if I have 2x more flow than I need or just a couple hundred gph to lose...

A post in hardware hasn't yeilded any advice on make/model...

Siphoning from the bottom is just one of the funtions of the U pipe, the other is to get the water moving back into the sump because of the 2 inches (10 gallons) of rise in the display tank needed to get to the OF box so the sump doesnt run dry.

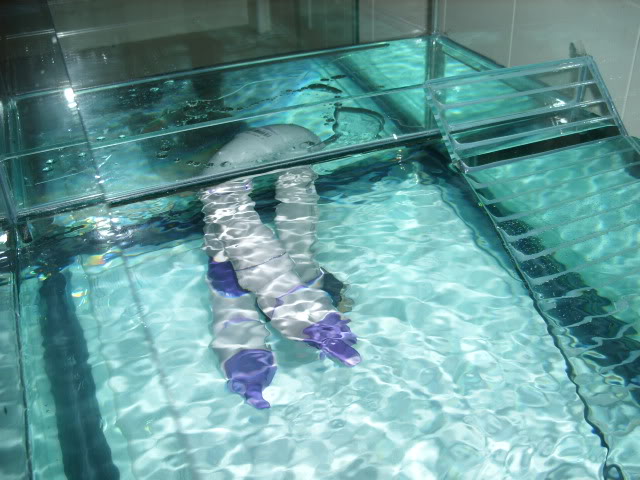

Adding a second U helped a little, so I am building a 3rd and 4th right now... pics in 30 min or so...

I think that point has drifted aside while I worked on other things. Back to it: whether or not I can return the magdrive24 (waiting to hear back from merchant) or recoup some of its value on craigslist I will need a less powerful pump. For the brand: I am willing to pay more for silence, though I don't know if I have 2x more flow than I need or just a couple hundred gph to lose...

A post in hardware hasn't yeilded any advice on make/model...

Siphoning from the bottom is just one of the funtions of the U pipe, the other is to get the water moving back into the sump because of the 2 inches (10 gallons) of rise in the display tank needed to get to the OF box so the sump doesnt run dry.

Adding a second U helped a little, so I am building a 3rd and 4th right now... pics in 30 min or so...