Hey everyone.

I am in the process of creating my first saltwater tank. A 30 gallon.

I have a 10 gallon tank below that I am going to use as a refugiam/sump.

I have 2 pumps that I can choose from: A pondmaster 500 gph and pondmaster 700 gph.

I chose the 500. Which, optimally, will turn over the tank about 17 times per hour.

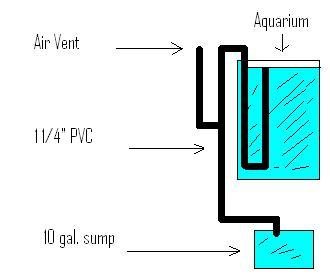

The tank is not drilled, so I decided to build an overflow out of 1 1/4" PVC pipe.

It functioned fine, BUT, the pump blew the overflow away.

There is just no way that the overflow can keep up with the pump.

So what do I do now?

Go with a smaller pump? (I think the 500 is perfect, so I don't want to do that)

Build the overflow out of 1 1/2 " PVC? Does anyone think the 1 1/2 will work? Will it make that much of a difference?

So that's my dilemma.

Any help would be appreciated.

Thanks!

Here's a crude sketch in paint.

I am in the process of creating my first saltwater tank. A 30 gallon.

I have a 10 gallon tank below that I am going to use as a refugiam/sump.

I have 2 pumps that I can choose from: A pondmaster 500 gph and pondmaster 700 gph.

I chose the 500. Which, optimally, will turn over the tank about 17 times per hour.

The tank is not drilled, so I decided to build an overflow out of 1 1/4" PVC pipe.

It functioned fine, BUT, the pump blew the overflow away.

There is just no way that the overflow can keep up with the pump.

So what do I do now?

Go with a smaller pump? (I think the 500 is perfect, so I don't want to do that)

Build the overflow out of 1 1/2 " PVC? Does anyone think the 1 1/2 will work? Will it make that much of a difference?

So that's my dilemma.

Any help would be appreciated.

Thanks!

Here's a crude sketch in paint.