JohnS

Aquarium Advice Regular

Very interesting thread. Thanks all for the info so far.

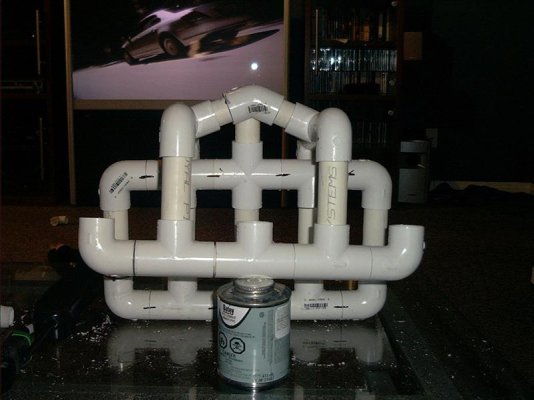

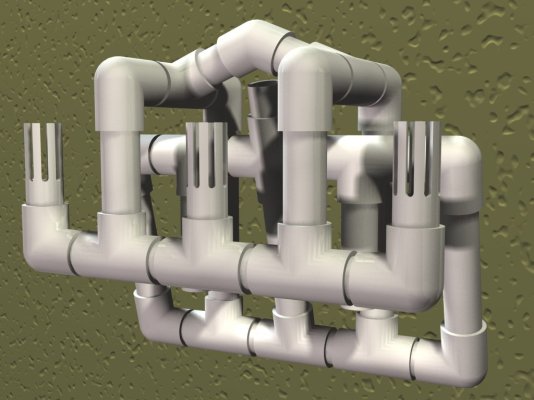

I'm thinking about using something like this to tie my 20g qt into a 30g garbage can (effectively giving my new fish 50g). Since I'm going with a smaller application, do you think I could build it with smaller diameter PVC? or would it be smarter to redesign it using fewer drains/ports? I'll probably use my Mag 7 as the return ph.

Any thoughts?

I'm thinking about using something like this to tie my 20g qt into a 30g garbage can (effectively giving my new fish 50g). Since I'm going with a smaller application, do you think I could build it with smaller diameter PVC? or would it be smarter to redesign it using fewer drains/ports? I'll probably use my Mag 7 as the return ph.

Any thoughts?