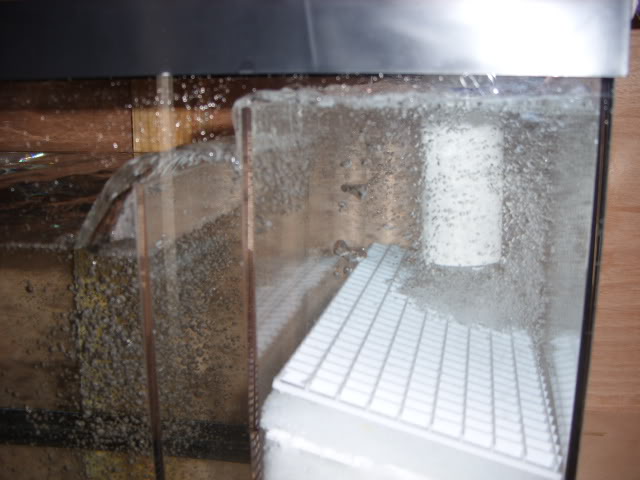

jsoong, thx for the pump silencing idea, I have it cushioned on top of a piece of filter foam, is that what you meant?

The spraybar I had before led to most of the flow coming out the tip of the cross, yet the multiple pathways left even the strongest flow pretty weak.

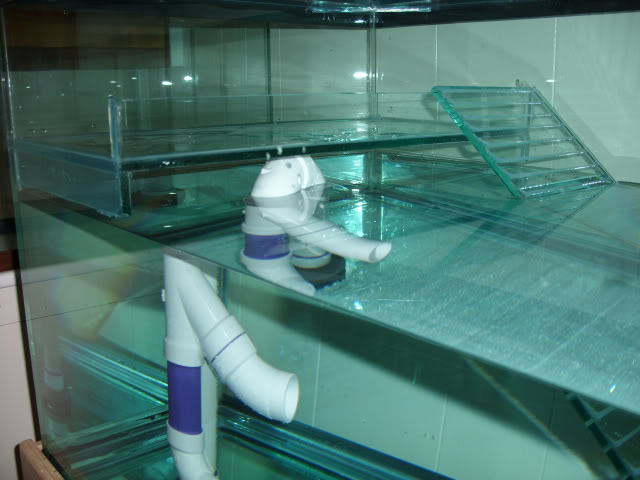

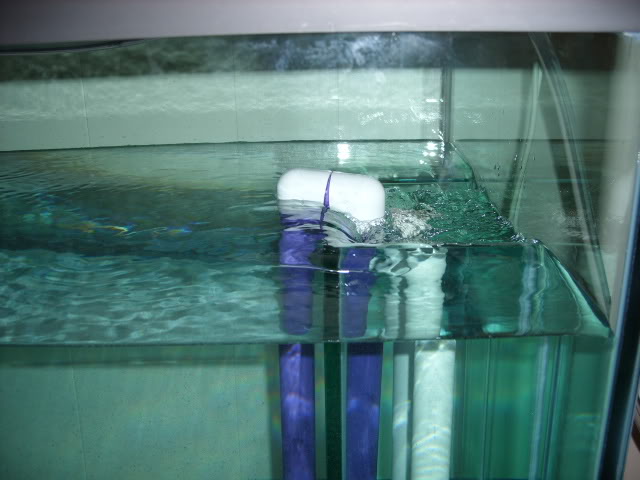

I have rebuilt with 1.5" pipe, and have a threaded coupling like you described, ziggy

My best ball valve is sealed too close to the T off from before, that and the lack of space and the desire to have as few joinings as possible led me to just pipe the pump to the bulkhead, with the ability to take apart to clean, add a valve, ect.

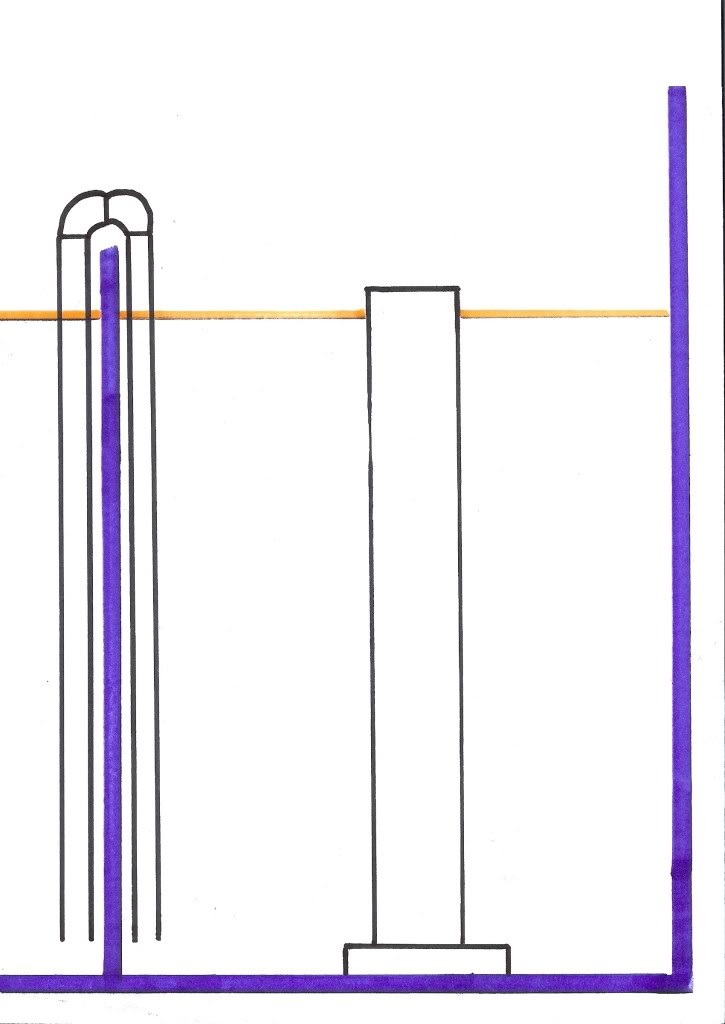

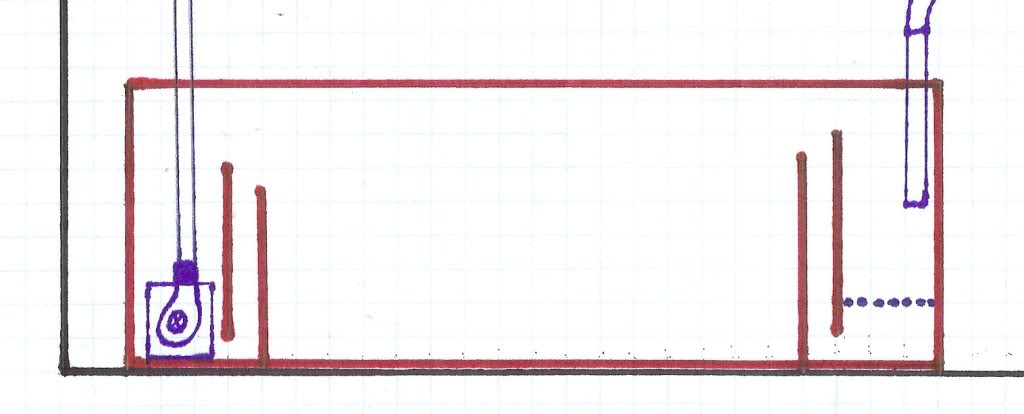

For the top, I had wanted some sort of flow to flush out the underside of the ramp/platform:

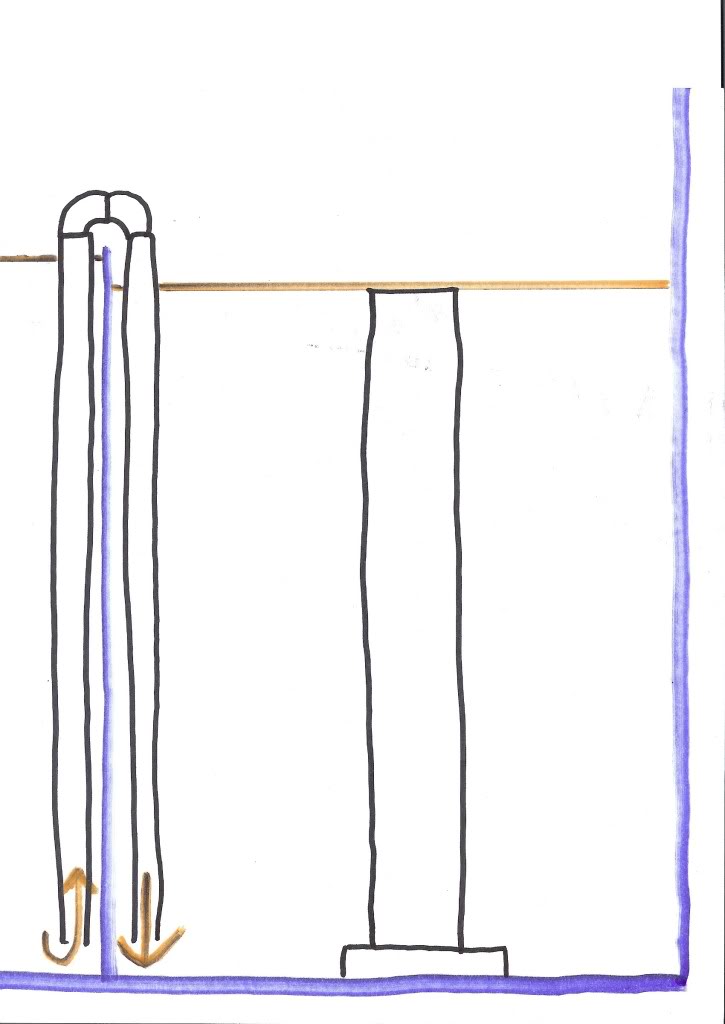

Though I think I will go with this instead, two outlets directed toward the opposit corner, with the lower one having the farthest reach:

With the Y split I hope to balance the flow, covering the greatest distance the length of the tank. Under the platform I hope enough water is moving in general, though cleaning with Python system might need to be more often if a dead spot developes.

I am going to tinker with the setup til I feel it's best it can be and cement it, then replace water.

If this works out, next I will figure out how to install teeth or eggcrate to keep turtles out of OF box, then U siphon and levels of standpipes.

Any thoughts?