Oh yeah, the pump smelled like a sewer. Not as bad as it did the first time I cleaned it when I took over the tank though. That time made me gag, I seriously thought I was going to hurl.

Here's the new tube run from pump to bulkhead

and from bulkhead to jets

Since the 3/4" threaded goes to a 1" hose barb, the inner diameter of that fitting is the same all the way through. Also, the 90 to the jets is a 1" female to 1" male, then a bushing to reduce the female to 3/4" for the jets. That means that the overall minimum ID of this is 3/4" (ID of the 3/4" threaded connector) vs 1/2" (3/4" hose barb connector), which is an increase of (0.75^2)/(0.5^2) = 2.25 or 125% more cross section. The maximum hose diameter went from 3/4" to 1-1/4", so that's (1.25^2)/(0.75^2) = 2.77 or 177% increase.

The Danner Manufacturing pump curve for the Mag12

http://www.dannermfg.com/instructionsheets/ZG100.PDF says that at 6 feet of head, you should get 950 GPH as long as you use 1.5" return piping.

So I would have to say that I'm pretty happy that I'm now getting 760 GPH. I expect that since the piping will 'slime up' over the next year, that the true maximum flow will eventually decrease by about 10%, putting it near 700 GPH, but it's a far cry better than the 433 max I was getting.

Also, here's a few YouTube videos that illustrate the difference

YouTube - 125 Reef - Plumbing Replacement

YouTube - 125 Reef - Plumbing Replacement & ATS Flow Increase

I also replaced the jets, because I had another set on hand...

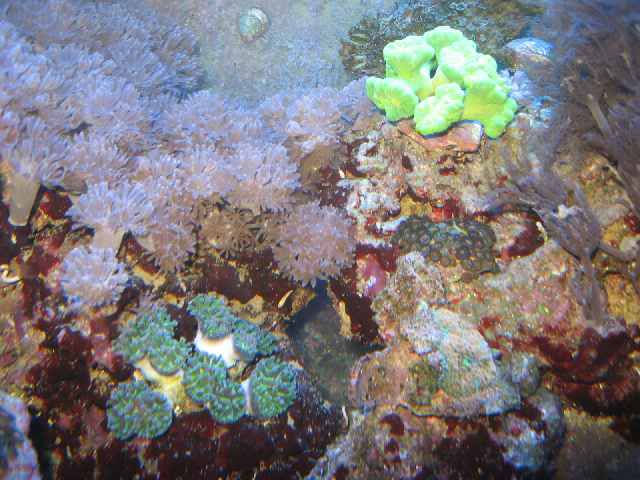

And I almost forgot, here's the screen

Getting better, slowly recovering. We'll see what doubling the flow does for growth and for phosphates, which have never been below 0.10 in this tank.