erichm20

Aquarium Advice FINatic

So I have decided to take it to the next level and add a sump to my current 55. I have some softies and LPS that are doing good but not thriving and I just can't defeat the cyano. I will be adding a skimmer (crazy I've gone this long without one) and will also have a refugium in one compartment of the sump so I can grow macro algae. So ive decided to go with a 20 L which won't fit in my stand so I'm building a new stand to accommodate the new sump, and I thought I would share the process.

These are the plans I used for the frame:

http://saltaquarium.about.com/od/diystandscabinets/ss/sbs2x4cabinetframe.htm

It's all 2x4 and I used 1/2" plywood for the top and bottom of inside (where the sump will sit).

I will post pics of the build later today.

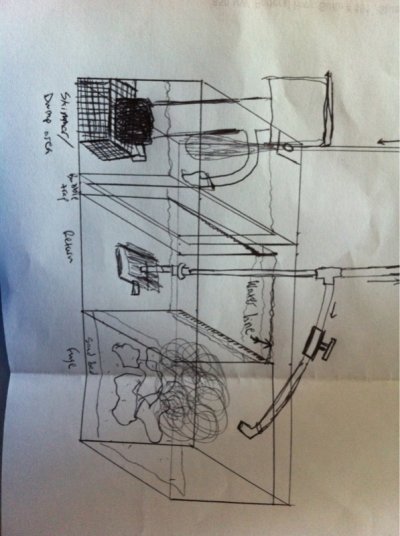

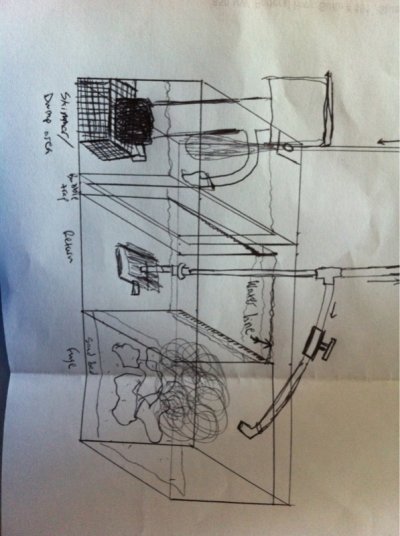

As for the sump I'm using an idea I found on melevsreef.

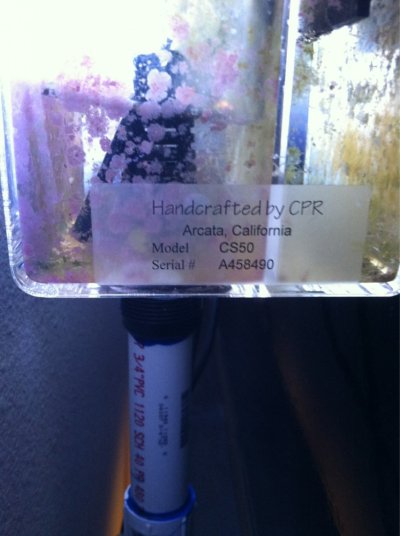

The first chamber is dump and skimmer section, then a 3 baffle bubble trap, 2nd chamber is the return area, 3rd chamber is fuge. I have a mag 7 pump and will t off the return line to feed the fuge. The fuge line will have a ball valve to control flow. The fuge baffle will have teeth (hopefully) and be 1.5" higher than the 3rd bubble trap baffle, which is 9" h.

These are the plans I used for the frame:

http://saltaquarium.about.com/od/diystandscabinets/ss/sbs2x4cabinetframe.htm

It's all 2x4 and I used 1/2" plywood for the top and bottom of inside (where the sump will sit).

I will post pics of the build later today.

As for the sump I'm using an idea I found on melevsreef.

The first chamber is dump and skimmer section, then a 3 baffle bubble trap, 2nd chamber is the return area, 3rd chamber is fuge. I have a mag 7 pump and will t off the return line to feed the fuge. The fuge line will have a ball valve to control flow. The fuge baffle will have teeth (hopefully) and be 1.5" higher than the 3rd bubble trap baffle, which is 9" h.