helicopter

Aquarium Advice Activist

Well this is my first summer with an aquarium and I am starting to get worried as I live in a dorm/apartment with no airconditioning. My room is already getting up to 82-83 and my tank is hitting 85-86 so I decided I should investigate chiller options. I saw a thermoelectric cooler designed specifically for the nanocube http://www.nanotuners.com/index.php?cPath=34 but it runs $90 and requires cutting into my nanocube. I decided I could engineer a cooler from scratch that fits my needs. So here is my experiment.

First things first, I purchased a 320 Watt Peltier cooler off of ebay for $13. It can run at 24 amps at 15.6 volts and pull 243.5 watts of heat. I already have a 13 amp 12-15 volt power supply laying around, if that doesn't do the trick then I can probably find one on ebay if I look hard enough for $20-30 which will (I think I got the 13 amp supply for around $20 shipped). The nanotuners ($90) TEC cooler has an 8.4 V 2.5 power supply (or a 12 V 4.5 amp for an additional $32.95) and the ICE PRobe (over $103) has a 12 V 4-5 amp power supply. So I should beat the heck out of both of them.

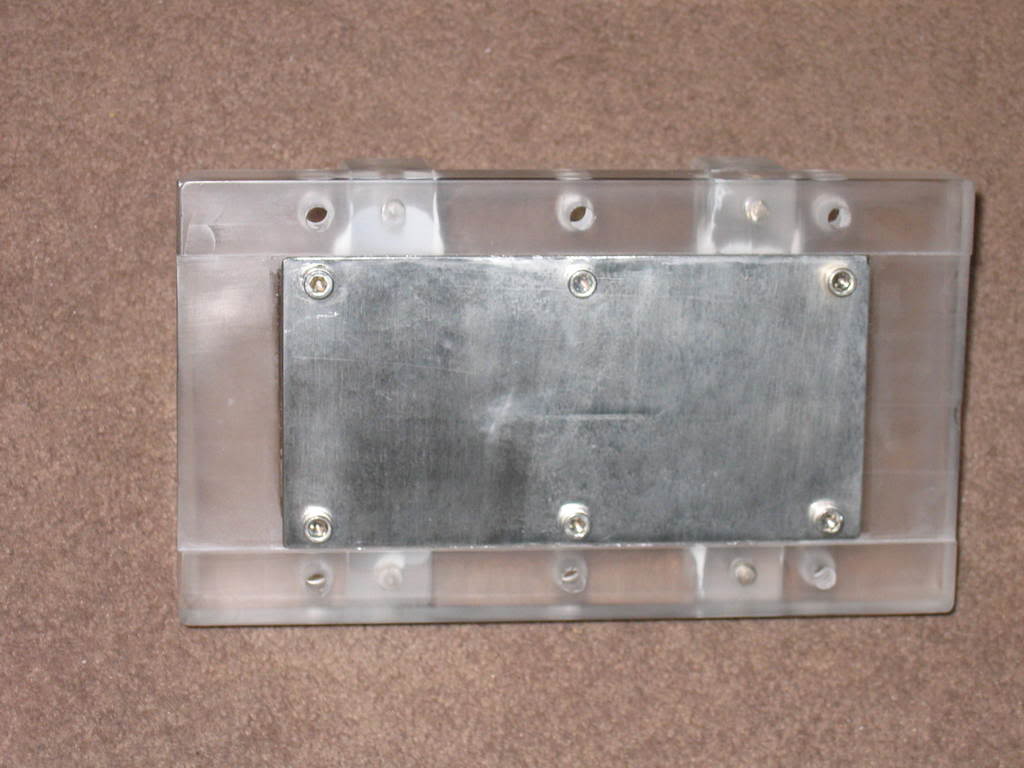

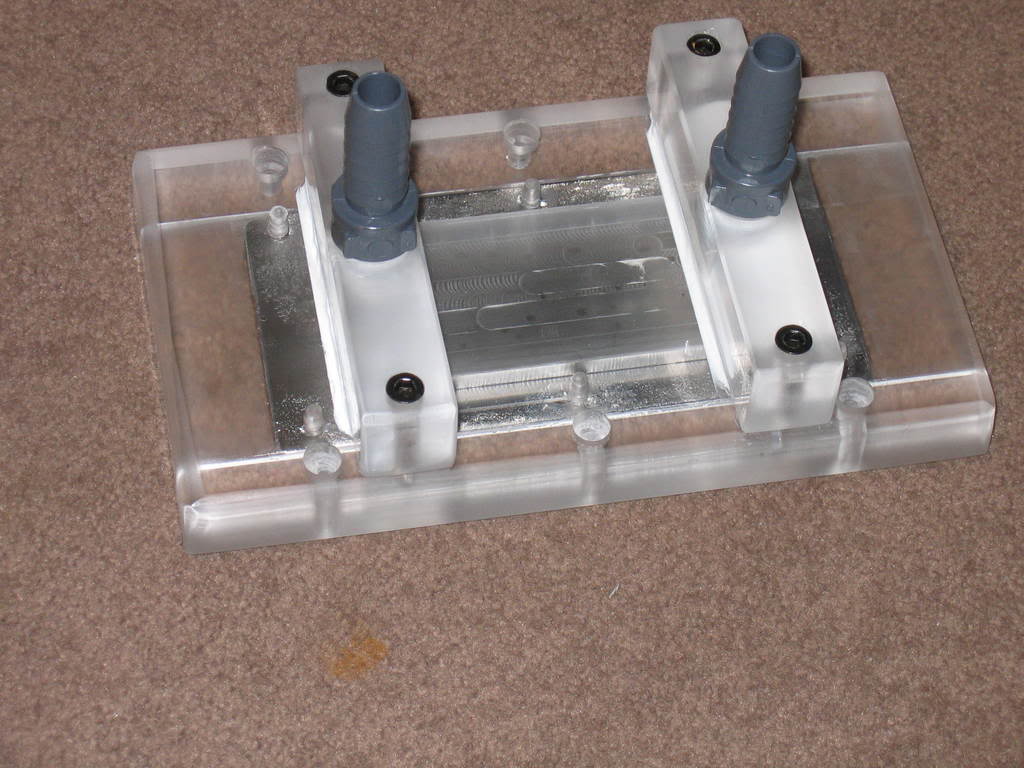

Heat Exchanger. Here is what has been really driving me crazy trying to figure out how I am going to accomplish this. The main concern is corrosion (I am building this for FW but with intention to use or sell for SW). Pretty much the only metal you could directly use is titanium and not have to worry about corrosion. I noticed the nanotuners TEC heatexchanger was a dinky Delrin piece. I was contemplating all these solutions that I could fabricate myself such as taking thin walled silicone (or other plastic) tubing and pot it in some thermally conductive substance (glue or something) that could make the thermal contacts. Or I could mill a channel in something like ABS, Acrylic (something non thermally conductive nor corrosive) and then bolt a piece of metal on top to seal it. I could drill and tap holes to put pipe fittings in. I could simply coat the side of the metal that will contact the water with some film (either spray on paint/epoxy or just lay down a very thin piece of something like polyamide) to prevent corrosion. Although the film will probably have a low thermal conductivity, it will be so thin it will not affect the heat transfer that much. But then I decided it would also be cool if I could devise a setup that most people could use regardless of whether they had access to a machine shop or special tools. So then I found out that there are heat exchangers made for liquid cooling CPU's that are almost exactly what I wanted to build. Here are a few of interest

http://www.coolermaster.com/index.php?LT=english&Language_s=2&url_place=product&p_serial=RL-D3A-CNU1. This is the one I think I am going to use, it has 1/4 tube fittings and the copper plate is removable so I can just take it off and spray or coat the one side that will contact the water to prevent corrosion.

Another one that is smaller and designed to fit a CPU

http://www.directron.com/clw0038.html

http://www.directron.com/chc35d06.html This one was interesting because it is gold plated and rather cheap. Although I found out that gold will corrode in salt water (although very slowly). I could also coat the inside but it seems like it will be more difficult.

There were a few other CPU/HD/GC heat exchangers that looked promising.

So now I have the heat exchanger, I either thermal tape the heat exchanger to the Peltier element or clamp it somehow, but now I need a fan.

Fan: I ordered a really crappy one (I am having regrets now) for $5 shipped. I think I will need a better one.

I have a few things in mind depending on exactly what I get such as building a new metal plate that can screw into both the heat exchanger and the fan. Let me know what you guys think. I think if this works out it could easily be scalable to larger systems (more gallon tanks). There is a next higher size Peltier element on ebay for about $19. The harddrive heat exchangers can easily accommodate two of these larger elements in parallel which if you had the proper power supply could be pulling a total of 60 amps at 15.4 volts. Each of the larger TEC can transfer 270.5W so thats a total of 541W theoretical. Of course you could expect maybe 1/2 that by the time it finally reaches your tank but thats still a good amount of cooling. That is about the amount of heat drawn (and thus dissipated into heat) by most larger tank's light and pumping systems.

First things first, I purchased a 320 Watt Peltier cooler off of ebay for $13. It can run at 24 amps at 15.6 volts and pull 243.5 watts of heat. I already have a 13 amp 12-15 volt power supply laying around, if that doesn't do the trick then I can probably find one on ebay if I look hard enough for $20-30 which will (I think I got the 13 amp supply for around $20 shipped). The nanotuners ($90) TEC cooler has an 8.4 V 2.5 power supply (or a 12 V 4.5 amp for an additional $32.95) and the ICE PRobe (over $103) has a 12 V 4-5 amp power supply. So I should beat the heck out of both of them.

Heat Exchanger. Here is what has been really driving me crazy trying to figure out how I am going to accomplish this. The main concern is corrosion (I am building this for FW but with intention to use or sell for SW). Pretty much the only metal you could directly use is titanium and not have to worry about corrosion. I noticed the nanotuners TEC heatexchanger was a dinky Delrin piece. I was contemplating all these solutions that I could fabricate myself such as taking thin walled silicone (or other plastic) tubing and pot it in some thermally conductive substance (glue or something) that could make the thermal contacts. Or I could mill a channel in something like ABS, Acrylic (something non thermally conductive nor corrosive) and then bolt a piece of metal on top to seal it. I could drill and tap holes to put pipe fittings in. I could simply coat the side of the metal that will contact the water with some film (either spray on paint/epoxy or just lay down a very thin piece of something like polyamide) to prevent corrosion. Although the film will probably have a low thermal conductivity, it will be so thin it will not affect the heat transfer that much. But then I decided it would also be cool if I could devise a setup that most people could use regardless of whether they had access to a machine shop or special tools. So then I found out that there are heat exchangers made for liquid cooling CPU's that are almost exactly what I wanted to build. Here are a few of interest

http://www.coolermaster.com/index.php?LT=english&Language_s=2&url_place=product&p_serial=RL-D3A-CNU1. This is the one I think I am going to use, it has 1/4 tube fittings and the copper plate is removable so I can just take it off and spray or coat the one side that will contact the water to prevent corrosion.

Another one that is smaller and designed to fit a CPU

http://www.directron.com/clw0038.html

http://www.directron.com/chc35d06.html This one was interesting because it is gold plated and rather cheap. Although I found out that gold will corrode in salt water (although very slowly). I could also coat the inside but it seems like it will be more difficult.

There were a few other CPU/HD/GC heat exchangers that looked promising.

So now I have the heat exchanger, I either thermal tape the heat exchanger to the Peltier element or clamp it somehow, but now I need a fan.

Fan: I ordered a really crappy one (I am having regrets now) for $5 shipped. I think I will need a better one.

I have a few things in mind depending on exactly what I get such as building a new metal plate that can screw into both the heat exchanger and the fan. Let me know what you guys think. I think if this works out it could easily be scalable to larger systems (more gallon tanks). There is a next higher size Peltier element on ebay for about $19. The harddrive heat exchangers can easily accommodate two of these larger elements in parallel which if you had the proper power supply could be pulling a total of 60 amps at 15.4 volts. Each of the larger TEC can transfer 270.5W so thats a total of 541W theoretical. Of course you could expect maybe 1/2 that by the time it finally reaches your tank but thats still a good amount of cooling. That is about the amount of heat drawn (and thus dissipated into heat) by most larger tank's light and pumping systems.