QTOFFER

Aquarium Advice Addict

I’m starting the most ambitious woodworking project I have ever attempted - an intarsia angelfish made with 31 pieces domestic and exotic hardwoods. I’ve built furniture before (my oak bed, two small aquarium stands, drawers, and lots of cabinets), but nothing this intricate.

Intarsia is a form of wood inlaying where carefully cut and shaped pieces of wood are joined together like a jigsaw puzzle to make a picture. The grain and natural color of the wood is used instead of paints or dyes.

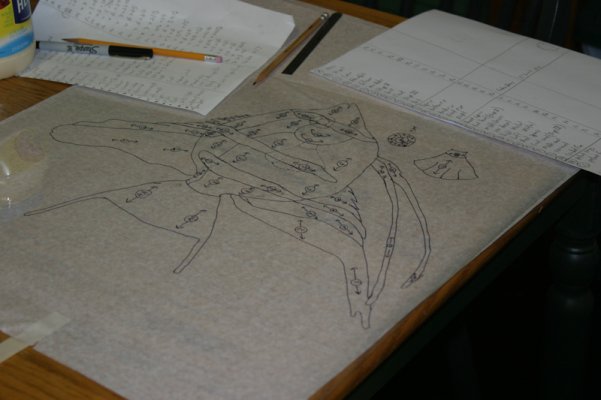

I haven’t seen any angelfish intarsia patterns in books or online, so I’m creating my own. I downloaded a pic of an angelfish off the net, enlarged it to size, and printed it out on several sheets of paper which had to be taped together. Then I traced the outline of the fish, its markings, and its external body parts on vellum paper.

These are pics of my vellum pattern taped onto the doors of my aquarium stand. I built the stand/storage unit/bookcase out of Southern white pine, and used unstained yellow poplar heartwood for the doors. The unit was given several coats of polyurethane finish – I’ll probably finish the intarsia the same way.

The fish will be attached to one door so they can open. I’m also going to make some intarsia plants to go on either side of the fish, but I haven’t drawn the patterns for those yet.

Intarsia is a form of wood inlaying where carefully cut and shaped pieces of wood are joined together like a jigsaw puzzle to make a picture. The grain and natural color of the wood is used instead of paints or dyes.

I haven’t seen any angelfish intarsia patterns in books or online, so I’m creating my own. I downloaded a pic of an angelfish off the net, enlarged it to size, and printed it out on several sheets of paper which had to be taped together. Then I traced the outline of the fish, its markings, and its external body parts on vellum paper.

These are pics of my vellum pattern taped onto the doors of my aquarium stand. I built the stand/storage unit/bookcase out of Southern white pine, and used unstained yellow poplar heartwood for the doors. The unit was given several coats of polyurethane finish – I’ll probably finish the intarsia the same way.

The fish will be attached to one door so they can open. I’m also going to make some intarsia plants to go on either side of the fish, but I haven’t drawn the patterns for those yet.