Hi,

I've run my DIY CO2 plan a few times thru this forum, so u may be quite familiar with it. However, I've encountered a problem and would like ur suggestions.

Briefly, this is my DIY CO2 setup:

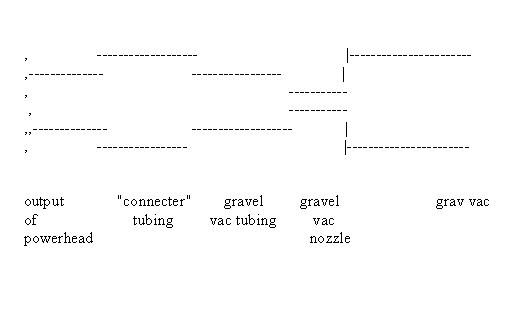

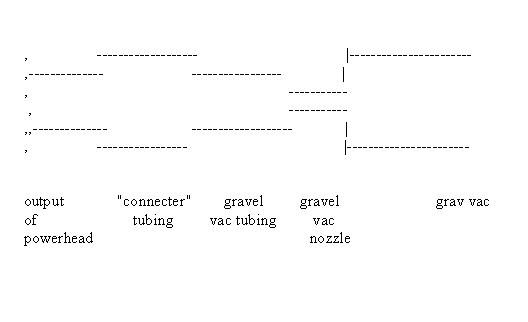

A 2L Coke bottle as the generator, connect that to a powerhead with a "venturi" input (like the Hagen 20 powerhead), then connect the output of the powerhead to the gravel vac with the sponge at the end of it.

However, I've run into a problem. It seems, that the input of the tubing to the gravel vac is a bit smaller than the output of the powerhead. A picture of what I'm saying is attached to this post.

This has resulted in some backflow of water out of the venturi. The pressure isn't much, and if I hold a piece a 10-15cm piece of airline tubing vertically, the pressure isn't enough to push the water out of the airline tubing. Also, I blew into the airline tubing (not smart, taste of aquarium water ), and bubbles started to develop in the gravel vac (which I'm assuming air is successfully being pushed in)

), and bubbles started to develop in the gravel vac (which I'm assuming air is successfully being pushed in)

However, my concern is whether or not the pressure will be strong enough, and also, over time when the output of the generator weakens, whether or not that pressure will be sufficient to introduce CO2 bubbles into the system.

What I'm asking, in your experience, will you think that the pressure from the CO2 generator is enough? If not, I prolly have to think about drilling a bigger hole into the gravel vac so the "connecter tubing" will fit straight into the gravel vac rather than the grav vac's original tubing

I've run my DIY CO2 plan a few times thru this forum, so u may be quite familiar with it. However, I've encountered a problem and would like ur suggestions.

Briefly, this is my DIY CO2 setup:

A 2L Coke bottle as the generator, connect that to a powerhead with a "venturi" input (like the Hagen 20 powerhead), then connect the output of the powerhead to the gravel vac with the sponge at the end of it.

However, I've run into a problem. It seems, that the input of the tubing to the gravel vac is a bit smaller than the output of the powerhead. A picture of what I'm saying is attached to this post.

This has resulted in some backflow of water out of the venturi. The pressure isn't much, and if I hold a piece a 10-15cm piece of airline tubing vertically, the pressure isn't enough to push the water out of the airline tubing. Also, I blew into the airline tubing (not smart, taste of aquarium water

However, my concern is whether or not the pressure will be strong enough, and also, over time when the output of the generator weakens, whether or not that pressure will be sufficient to introduce CO2 bubbles into the system.

What I'm asking, in your experience, will you think that the pressure from the CO2 generator is enough? If not, I prolly have to think about drilling a bigger hole into the gravel vac so the "connecter tubing" will fit straight into the gravel vac rather than the grav vac's original tubing