I am planning a bit of an experiment and thought I’d get some feedback. I am moving my tank in two weeks time and will start the experiment then.

The premise of the experiment is that yeast in an aerobic environment will still produce CO2, but not alcohol. It is the alcohol in our brews that kills the yeast and limits the life span of the brew. If you could find a way to aerate the brew it would last much longer and produce a much larger amount of c02 before the brew dies..... In theory anyway.

The problem with this of cause is that you will “water” down your c02 and combine it with huge amounts of oxygen. But what if you only pumped air in for say 5 minutes every hour and could keep it from entering you reactor chamber??

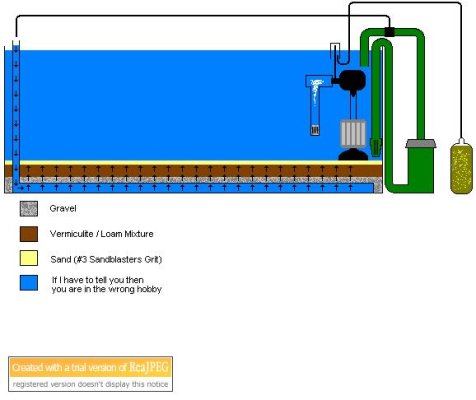

It will be easy enough to run a small (very,very small) airpump into the brew and keep it all airtight and just have a timer on the air pump. My DIY reaction chamber is a little different to others in that I use a power head venturi fitting to pump the c02 into the reactor so I don’t have my brew connected directly to it. Instead it bubbles into a small chamber on the lip of my tank (about the size of a PH tester vial) and is sucked out by the venturi from there.

This means that while the air pump is on the excess gas that can’t be picked up by the venturi will simply escape from the vial-chamber thingy. My reactor chamber is very,very efficient so any oxygen that is drawn it will be dissolved very quickly (This could be beneficial for the tank as well?? Maybe?)

In short I don’t think it will work, but my tank has been running really well for the last year and a half and I miss all the playing around with stuff. I think the biggest problem will be getting an airpump to work in a pressurised environment. A check valve on the pump will be needed to stop the brew being forced back into the airpump (Could get ugly)

As I said I’ll be moving the tank in 2 weeks(give or take) and will start the experiment after that. Will let you know how it goes.

Any thoughts??

The premise of the experiment is that yeast in an aerobic environment will still produce CO2, but not alcohol. It is the alcohol in our brews that kills the yeast and limits the life span of the brew. If you could find a way to aerate the brew it would last much longer and produce a much larger amount of c02 before the brew dies..... In theory anyway.

The problem with this of cause is that you will “water” down your c02 and combine it with huge amounts of oxygen. But what if you only pumped air in for say 5 minutes every hour and could keep it from entering you reactor chamber??

It will be easy enough to run a small (very,very small) airpump into the brew and keep it all airtight and just have a timer on the air pump. My DIY reaction chamber is a little different to others in that I use a power head venturi fitting to pump the c02 into the reactor so I don’t have my brew connected directly to it. Instead it bubbles into a small chamber on the lip of my tank (about the size of a PH tester vial) and is sucked out by the venturi from there.

This means that while the air pump is on the excess gas that can’t be picked up by the venturi will simply escape from the vial-chamber thingy. My reactor chamber is very,very efficient so any oxygen that is drawn it will be dissolved very quickly (This could be beneficial for the tank as well?? Maybe?)

In short I don’t think it will work, but my tank has been running really well for the last year and a half and I miss all the playing around with stuff. I think the biggest problem will be getting an airpump to work in a pressurised environment. A check valve on the pump will be needed to stop the brew being forced back into the airpump (Could get ugly)

As I said I’ll be moving the tank in 2 weeks(give or take) and will start the experiment after that. Will let you know how it goes.

Any thoughts??